Features

Agronomy

Fertility and Nutrients

Row spacing research offers clues to optimum stand establishment

Researcher Dr. Guy Lafond has been in the row spacing research game for a couple of decades, and he says that when growers look at the myriad research studies conducted in Western Canada during the past 30 years, they have to dig beneath the surface to figure out actual methods used to conduct the studies.

March 18, 2010 By Top Crop Manager

Researcher Dr. Guy Lafond has been in the row spacing research game for a couple of decades, and he says that when growers look at the myriad research studies conducted in Western Canada during the past 30 years, they have to dig beneath the surface to figure out actual methods used to conduct the studies.

“The devil is in the details,” says the Agriculture and Agri-Food Canada Indian Head Research Farm researcher. “There can be a lot of confounding effects in research studies with respect to seeding rates, fertilizer management, measurement methods, field condition, equipment used, plot layout and management and experimental design.”

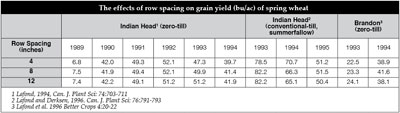

Lafond has conducted several row spacing trials of his own, and has been part of enough studies to see some general trends develop. He has summarized many of the western Canadian research trials and reports, “Although one could argue that, for certain crops, the risk of reduced yields with row spacings in the range of 10 to 12 inches is frequent enough to cause concern, one has to keep in mind what the absolute differences are and what the overall benefits are when considered on a whole farm basis. There were enough positive studies to show that, in absolute terms, high yields can be maintained with 12-inch (30-centimetre) spacings without compromising the yield potential.”

Lafond conducted several studies in the early to mid-1990s and continues to follow results in row spacing studies. He believes, “While a very clear and precise statement to the effect that row spacing in the range of four to 12 inches has no effect on grain yield in spring wheat is not possible, we can nonetheless state that, providing proper crop production practices are used with wide row spacings, a yield reduction should not occur.”

|

New research to dig deeper

In 2009, Lafond instigated a new study on row spacing. The research trial is comparing four row spacings of 10, 12, 14 and 16 inches, along with different rates of nitrogen (N). The trial is using an air drill specially designed for plot work involving a commercial opener that allows the openers to be easily moved to adjust row spacing. The drill uses independent openers that places seed and fertilizer in two separate narrow bands, with fertilizer located approximately 0.75 inches deeper and 1.5 inches to the side of the single seed row. “When farmers started experimenting with 12-inch spacing, people said, ‘no way, that won’t work.’ Now we are seeing commercial seeders with 14-inch opener spacing so we want to see how far row spacing can be pushed,” says Lafond.

He cautions, though, that with wider row spacing, careful attention must be paid to fertilizer management. Lafond says that moving from nine to 12 inches will increase the concentration of the fertilizer near, or with, the seed by 30 percent. “There may be a point where the fertilizer concentration is too high, and causes germination problems with wider row spacing.”

With the first-year harvest just completed, Lafond cannot provide any data, but says general observations did not see any difference in stand establishment, the amount of tillering and overall biomass production in the oat crop.

Shank spacing does not equal row spacing

Garth Massie, agronomist with Morris Industries, says another consideration is seedbed utilization. For example, a knife that places seed in a one-inch band with a 12-inch row spacing has a seedbed utilization of 8.33 percent. That same opener on an eight-inch placing would have a seedbed utilization of 12.5 percent. Whether that makes a difference though, is still debatable.

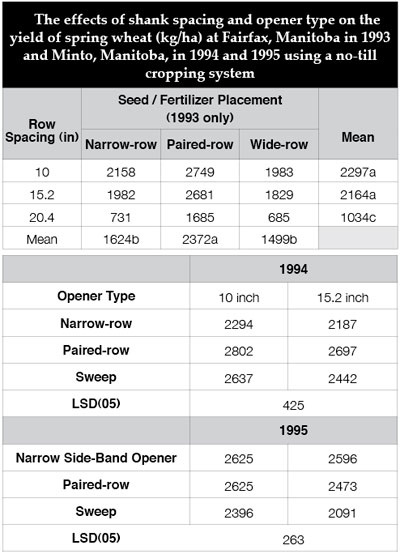

One study conducted at the Conservation Tillage Productivity Centre in Minto, Manitoba, compared narrow side-band, paired row, and sweep openers on both conventional and zero-till land. The paired row opener placed seed five inches apart in a narrow band. The side band opener placed seed in a band above and to the side of the fertilizer. The sweep spreads the seed and fertilizer across a five-inch area.

|

Under zero tillage, the paired row opener tended to produce slightly higher yield, with no difference between the narrow and the sweep opener. However, the authors claimed that problems with seed and fertilizer separation occurred with the narrow opener, which would explain the yield reduction.

Massie says that many of the drills that Morris sells now go out with their paired row opener on 12-inch shank spacing, essentially creating a paired row that is four inches apart, with eight inches between the paired rows. He says many farmers make that decision based on a combination of factors, including increased seedbed utilization, canopy closure, weed competition and residue clearance. “There are strengths and weaknesses to everything. With wider shank spacing and paired row openers, there is more soil disturbance, which may help to speed the soil warming. But not everyone likes that, so others choose a narrow sideband opener if they want less soil disturbance,” explains Massie. “A lot comes down to personal preference.”

| Potential benefits of wider row spacings Researcher Dr. Guy Lafond, with the Agriculture and Agri-Food Canada (AAFC) at Indian Head, Saskatchewan, offers observations on the benefits of wider row spacings. 1. Residue Management: The most important reason for using wide row spacings under zero-tillage has to do with the challenge of seeding through very heavy residue conditions, especially when combined with wet soil conditions, i.e., less soil and residue disturbance. The rule of thumb has long been that shank spacing should be greater than stubble height. 2. Water Conservation: Research by Cutforth and McConkey at AAFC Swift Current has shown that wheat yields can be increased by 11 percent when seeding into tall (12- to 14-inch) stubble compared to six-inch stubble. The tall stubble traps more snow and slows down evaporation loss in the spring. This yield advantage is also evident with pulse and oilseed crops. 3. Equipment Efficiency: A 33-foot air drill with nine-inch spacing has 44 openers. By moving to a 12-inch spacing, the width of the machine can be increased to 44 feet for the same horsepower. Seeding and tractor hours would be reduced by 33 percent. With the reduced cost of openers and their reduced replacement costs, the economic advantage of wider rows can also help reduce risk. It can be argued that changes in row spacing can actually improve the timeliness of the seeding operation and lower the long-term machinery costs at the same time. |