Features

Insect Pests

The next generation of customized crop treatments

Researchers design new systems using nanoparticles to target specific crop pests without harming beneficial plants and insects.

October 4, 2023 By Donna Fleury

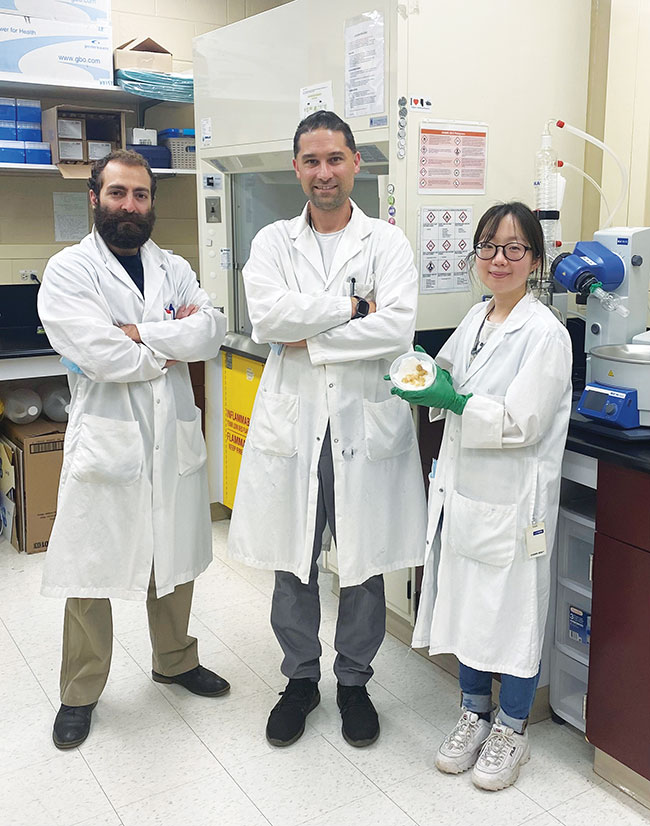

Core team members in the NanoLab: Dr. Armen Tchobanian (left), Dr. Damin Kim (right), Dr. Justin Pahara (centre).

Core team members in the NanoLab: Dr. Armen Tchobanian (left), Dr. Damin Kim (right), Dr. Justin Pahara (centre). Researchers are developing the next generation of crop treatments using nanotechnology to help optimize the management of agricultural pests for western Canadian producers. These next-generation crop protection products are designed to be targeted, effective, and efficient so producers can receive better protection while using less spray. Being able to target specific crop pests reduces the risk of harming beneficial plants and insects while improving biodiversity.

“In our research program, we are trying to help solve high-level problems or barriers by looking to the next generation of crop treatments,” says Justin Pahara, a research scientist with Agriculture and Agri-Food Canada in Lethbridge, Alta. “On one hand, producers need access to economical crop treatments for agricultural pests, but they also face other challenges such as increasing pesticide resistance, more regulation, and priorities to improve biodiversity. Our current crop treatments tend to be broad-spectrum, typically targeting the anatomy level, such as insecticides that act on the central nervous system of insects. These broad-spectrum chemistries can also affect other organisms, including humans and animals. Our research is focused on leveraging nanotechnology to design target-specific crop treatments.”

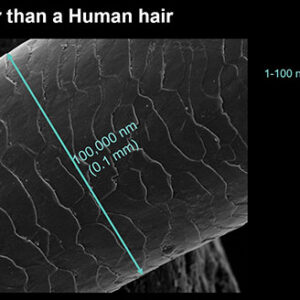

Pahara explains that nanotechnology involves working with very small structures, not the smallest, but larger than the level of atoms or small chemicals such as a water molecule or molecules of typical broad-spectrum pesticides. Using a human hair for comparison, which is about 100,000 nanometers across, a nanostructure is typically one to 100 nanometers in size. These microscopic nanoparticles are bound with active ingredients that affect a specific plant or insect and can be customized to produce a variety of desired outcomes.

“In our Lethbridge NanoLab, our research involves combining nanoparticles and different nucleic acids such as DNA or RNA to create new active ingredient formulations,” explains Pahara. This is a similar technique to new drug development and delivery, such as COVID-19 vaccines. “We are also developing nanocarriers made from zinc or magnesium or various other compounds that are not harmful to plants. These carriers will bind to new active ingredients and deliver this formulation directly to specific hard-to-manage crop pests such as lygus bugs or cutworms. One of the beautiful things about nucleic acids is we can think of DNA as the programming language of biology. This allows us to reprogram nucleic acids to allow for addressing multiple pests in one application or to reprogram the active ingredients to target something else. For example, if an active ingredient should become resistant for whatever reason, we should be able to tweak and reactivate the active ingredient to be effective, unlike the challenges with traditional pesticide resistance issues.”

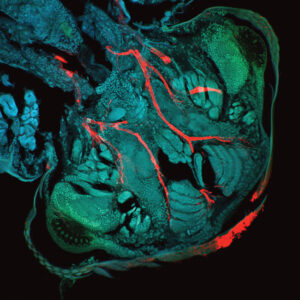

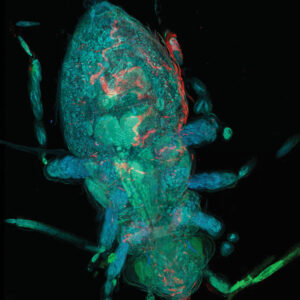

One of the priorities is to understand where the active ingredients end up in the insect or plant. This ongoing work is still not completely well understood, even in traditional pesticides. “We are currently working on new tools that will create 3-D images from fluorescent nanoparticles that track where within the insect these nanoparticles are going,” says Pahara. “For example, in research with lygus, our preliminary information is showing the active ingredient is entering the respiratory system. A big question in our research is to determine where the active ingredient is going in both insects and plants, as it is essential to selecting the most effective nanoparticle and active ingredient combination to target that species. This also ensures that the active ingredients reach the area within the insect or plant where they are most effective.”

These next-generation crop treatments will be delivered the same way that producers currently apply pesticides. The goal is for producers to be able to use the existing infrastructure, systems, and application methods with no additional costs. “We have created a special spray chamber using industry nozzles to test and spray small volumes of our formulations using as much of a real-world scenario as possible,” says Pahara. “This chamber took about a year to develop, including the safety of working with these small nanoparticles in a spray system.”

Pahara’s NanoLab is also using new robotic technology that enables them to test different nanoparticle combinations on many species of pests on a large scale. This novel approach makes the screening process much more high throughput, allowing for testing thousands of different formulations very quickly, rather than focusing on one formulation at a time. This approach leverages numbers to speed up the process and focus on optimizing the most effective formulations. While other groups around the world are working in this area, much of the work so far is still bespoke on the benchtop and small scale.

Another priority for the lab is the development of methods that regulatory agencies could use for safety and efficacy assessments of nanoparticles and for confirming the targets of active ingredients and environmental toxicity.

“When it comes to regulation, we recognize that both Canadian and international regulators have to be on board, as Canada exports many products internationally. We are developing new methods that could be leveraged by the Standards Council of Canada and stakeholders around the world to enable regulators to assess this new class of crop treatment,” says Pahara. “We aim to have products and test methods approved and ready to go by the end of the decade.

“Our team is also interested in working with collaborators, and we encourage industry and companies in Alberta or across Canada to reach out to participate in product development. We are really trying to ramp up and hope that by 2024 we can open up the lab to other collaborators who will also be able to benefit from these new systems. Our lab can be a mini-hub of innovation in developing these next-generation crop treatments, leveraging existing tools and infrastructure. Our team would do the work, but if someone else from academia, government agencies or private companies in Canada and around the world is trying to develop nucleic acid active ingredients, then we could actually swap those into our pipeline and screen to see how they interact with these nanoparticles. We already have partners working on active ingredients for kochia and have projects in the coming year for blueberries, canola, flea beetles, and are continuing our work with cutworms and lygus. We are also in discussions with a seed treatment company. It is exciting to see the support and buy-in from other folks who see the potential in this new technology.”

Producers are also welcome to reach out with questions or input regarding product development. “We recognize this is new technology and nanotech is not always well understood. Ultimately, all of these products will have to go through regulatory approvals. Our goal is to develop nanoparticle crop treatments that can help producers reduce costly crop spraying, increase production, and expand their market opportunities internationally and abroad,” says Pahara. “We expect to have these new-generation crop treatments available by the end of the decade.”

The project is funded by Agriculture and Agri-Food Canada, Western Grain Research Foundation, Saskatchewan Wheat Development Commission, Alberta Innovates, Alberta Wheat Commission, Results Drive Agriculture Research, and Canadian Light Source Synchrotron.