Features

Canola

Diseases

Technology

Patent awarded for biosensor that can forecast sclerotinia disease in canola

Final testing underway for portable biosensor that sends real-time disease levels to growers to help optimize disease management.

November 8, 2023 By Donna Fleury

Researcher Xiujie (Susie) Li awarded a patent for her nano biosensor technology in February 2023.

Photos courtesy of InnoTech Alberta.

Researcher Xiujie (Susie) Li awarded a patent for her nano biosensor technology in February 2023.

Photos courtesy of InnoTech Alberta. Sclerotinia stem rot is one of the most serious diseases of canola and can lead to significant crop losses depending on conditions. When warranted, fungicide applications can help manage the disease; however, timing is critical, and the fungicide must be applied before symptoms of stem rot are visible. Therefore, developing forecasting tools that can help optimize disease management will be valuable for growers.

Researcher Xiujie (Susie) Li with Innotech Alberta was awarded a patent for her nano biosensor technology in February 2023. “I have been working on this technology for several years and am pleased to see a patent awarded for these efforts,” says Li. “The team has made a lot of progress and expects to have a commercial product ready for growers within the next three years. We are finalizing the testing of the final product, a portable biosensor, which sits in the field detecting specific fungal spores in the atmosphere. The sensor will send disease levels in real time to the grower.”

The key to the biosensor is understanding the plant disease triangle that involves the environment, the host and the pathogen. “As growers know, the pathogen is key to disease development,” explains Li. “Even if environmental conditions are favourable for disease development, unless the pathogen is present, the disease won’t develop. Therefore, we have developed the biosensor to detect the pathogen, in this case, the sclerotinia fungus that causes sclerotinia stem rot in canola during flowering. The biosensor technology is designed to continually detect and monitor the pathogen levels in the field during the risk period so growers can make informed and timely decisions on disease severity and make informed management decisions.

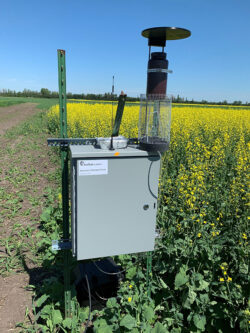

“The technology has evolved from a proof of concept and testing with large equipment in the lab and growth chambers to a field deployable or portable biosensor unit. Last year, we had six biosensor unit prototypes deployed to the field for testing. We needed to find out if the biosensor would work in the real environment. The portable biosensor unit is battery-operated and placed in the field just before flowering for about a month. The unit is enclosed in a secure metal box anchored to the ground. Overall, the biosensor worked better than we initially expected, and we have now added automation to it. Our goal is to make the biosensor user-friendly and worry-free so growers can place it in the field at the beginning of flowering and leave it alone until the risk has passed. The biosensor will send them daily spore levels in a text message, allowing them to easily forecast disease risk.”

The unit collects samples and runs them automatically through a portable detector chip inside the biosensor, and then sends the data directly by text message to a cell phone. The small chip, initially designed for medical analysis of DNA or proteins, is formatted using sclerotinia antibodies to target the sclerotinia spores in the atmosphere. Although the sensor is designed to run and collect samples 24/7, the biosensor has been set to detect disease levels and send the data once a day to save the battery. The unit is designed to also send out a warning once a threshold level of spores has been detected, providing timely information for making fungicide application decisions.

So far, the field testing has provided good results, confirming that the biosensor is successfully able to detect the spores and report changing precipitation and increasing disease levels. In field testing, the portable chip was able to predict spore populations that were similar to actual field spore population measurements. Some of the prototypes performed well, although a few units required some troubleshooting for both software and hardware issues.

The portable biosensor unit being tested under field conditions. The unit is battery-operated and placed in the field just before flowering for about a month.

“This year we placed one biosensor for each 160 acres in field testing, which worked very well,” adds Li. “In 2024, we will be further testing the range of the biosensor to see how many biosensors need to be deployed in an area. We will start with five sensors for 640 acres or one section of land, putting one in the middle of the section and one in each corner. We know the wind blows from different directions, so this information will help us determine whether one biosensor might be sufficient for one section or maybe even a larger area, or how many biosensors need to be deployed in a given area.”

Once the field testing and troubleshooting are completed, Li plans to work with a manufacturer to build and assemble the biosensor units. The biosensor will be a one-time investment, but the portable detector chip will have to be updated every year because the antibodies only last about six months. The costs are expected to be fairly reasonable for growers, with each unit estimated to be approximately $1,000 or less, plus the annual updated chip.

“We are excited about the success of the biosensor technology and expect to be able to make it commercially available within three years,” says Li. “This user-friendly disease forecasting tool will be a big benefit for canola growers in detecting disease levels, managing disease risk and making timely decisions regarding fungicide applications. Once the technology is commercialized for sclerotinia stem rot, our first target, then we can turn to other diseases such as Fusarium head blight. The technology will be deployable anywhere and for diseases where antibodies are available. The technology will be capable of detecting a wide range of diseases in various environments, such as detecting COVID-19 in airports, for example, and has many other potential applications. In the very near future, this patented biosensor technology will offer a user-friendly tool for managing challenging diseases in agriculture and other industries.”