Features

Agronomy

Tillage

Variable rate application coming of age

NASA meets ground truths in agriculture.

October 18, 2008 By Bruce Barker

NASA meets ground truths in agriculture.

|

| Variable rate technology may help improve profitability on variable land. Photo by Bruce Barker |

Variable rate application has been touted for years as the next big change in agriculture. The technology has been around for a while, from guidance through yield mapping to variable rate controllers. But aside from producing a lot of pretty yield maps, getting to the next step and successfully implementing variable rate prescriptions has been tough.

For farmers working on variable rate application on their own, it required a crash course in computer programming. But that may be changing. Mosaic’s InSite VRN (variable rate nutrient system) is one of several new variable rate programs that more farmers are trying out.

“Yield mapping is important, but it is hard to take it to the next step on your own. Our land has a lot of variability in it, with some salinity, so we knew that variable rates would make sense, but we needed a program that would help us determine what to do,” explains Kevin Slimmon, who farms near Stoughton, Saskatchewan with his father Dale and Uncle Earl.

The Slimmons settled on the InSite VRN program for a number of reasons. Slimmon liked the way the InSite VRN program set up management zones and the agronomic approach for developing prescription maps. There was also no cost if the decision was made not to proceed with variable rate application after conducting the economic analysis.

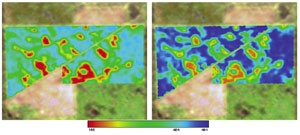

| Benning NH 7 8 14 WB |

|

| Left: flat rate application Estimated profit for field: $106,412.80 Estimated profit per acre: $345.17 Right: variable rate application Estimated profit for field: $124,454.80 Estimated profit per acre: $403.69 |

Remote sensing forms the basis of InSite VRN

The Field InSite tool began in the early 1990s as a joint project with Cargill, NASA and the USDA to examine the potential for remote sensed information to be used for gathering merchandising intelligence such as crop yield potential and crop acreage. However the technology proved too expensive for the program. Cargill determined that because the program had been developed to accurately estimate yield potential, it could be used to develop management zones and prescription fertilizer applications. Mosaic eventually took over the program.

“The InSite program really allows us to manage a huge amount of data with remote sensing. Based on the early work, the satellite imagery can be correlated to yield, which allows us to set up yield management zones,” explains Tom Staples, an agronomist with Echelon in Weyburn, Saskatchewan. “By working with a grower, we can easily develop variable rate prescriptions without intensive soil sampling or yield mapping.”

With the InSite VRN program, remote sensing with satellite imagery helps to establish management zones and yield potential maps. The yield potential map estimates the yield potential of each pixel representing a 15 metre by 15 metre square on the satellite image independently, resulting in a yield map similar in appearance to a combine yield map. This information can then be used to establish yield goals based on specific environmental conditions, sampling strategies and variable rate fertilization strategies.

To get started, farmers work with their local Mosaic agronomist to select the candidate fields and established field boundaries using GPS. Field histories for the last five years, including crop rotations, average yields, average organic matter and target yields, are put into the software program.

InSite VRN estimates crop demand for nutrients for each pixel on the field image. The soil supply is then estimated. Soil supply is calculated from organic matter maps, nutrient mineralization estimates from organic matter, soil residual nutrient (from soil sampling), and other sources of nutrients (irrigation water, top dress applications, starter fertilizers) for each pixel on the field image.

The difference between crop demand and soil supply is then calculated for each pixel and the difference is made up with fertilizer. Essentially, a nutrient balance is calculated for each pixel in the field, the amount of fertilizer needed to meet crop demand is calculated, and a variable rate prescription map is developed. The economics of the variable rate prescription map is then calculated and can be compared to the grower’s flat rate fertilizer program.

Up to this point, there is no cost to the grower for the consultation.

If the economics warrant, a variable rate prescription map is downloaded to a card which is used with the variable rate controller in the field. The cost of the download is $7.50 per acre.

Putting it into practice – liquid N

In 2007, the Slimmons tried out InSite VRN on 600 acres of wheat and

800 acres of canola on their 10,000 plus acre farm of canola, peas,

hard red wheat, durum, canaryseed and barley. They use a Seed Hawk

toolbar with shanks on 12 inch centres. Fertilizer and seed are placed

in separate bands. They have a Flexi-Coil air tank, which is used for

seed, and a dry blend fertilizer of P-K-S. Liquid N is metered to the

fertilizer band separately from a 2100 gallon liquid cart.

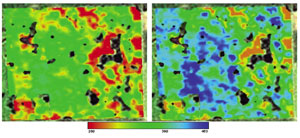

| Slimmon Sec 4 10 9 W2 |

|

| Left: flat rate application Estimated profit for field: $194,350.10 Estimated profit per acre: $348.29 Right: variable rate application Estimated profit for field: $217,748.40 Estimated profit per acre: $390.22 |

Slimmon used an Outback GPS guidance system, an AgLeader PF3000 monitor and a Raven rate controller to control the fertilizer N flow rate to the toolbar.

Typically on canola, Slimmon applies a flat rate of 30 to 32 gallons of N per acre, or about 92 pounds actual N. His approach with the InSite VRN was to apply lower N rates on the areas of the field that have lower yield potential, and higher N rates on the areas with high yield potential. In 2007, the rates varied from a low of approximately 15 pounds N actual up to 110 pounds N actual.

“I think we set the low rates too low last year. This year, we plan on setting the low rates in the 40 pound actual N range,” says Slimmon. He used the same approach

in wheat, cutting back N rates on the low yield potential areas, and increasing the rates on high potential areas. By way of example, the economic analysis on a 558 acre canola field from 2007 showed a savings of 26 pounds N per acre with the variable rate application, for a savings of $11.77 per acre. The potential yield benefit of variable rate N was estimated at $30.15 per acre, for a total variable rate advantage of $41.93 per acre: $23,400 increased revenue on the field.

While his actual 2007 yields were somewhat disappointing because of the hot, dry summer weather, Slimmon estimates that he made somewhere between $20 to $25 per acre more with variable rate application, easily providing a return more than the $7.50 per acre cost for the InSite VRN prescription maps.

For 2008, Slimmon plans on using InSite VRN on half to three-quarters of the farm. He estimates that he will save about 150 tonnes of N, with potential benefits well into the hundreds of thousands of dollars. “That’s a huge saving, and we also expect that our yields will be higher, too,” says Slimmon.

Similar approach with anhydrous ammonia

In Weyburn, Saskatchewan, Terry Benning also tried the InSite VRN program in 2007. He farms about 12,000 acres with his brother Gord and father Clif. The Bennings grow oilseeds, pulses and cereals, and used the InSite VRN program on 5500 acres in 2007.

“We were interested in trying out InSite VRN four years ago, but weren’t sure if the technology was ready. We had another look at it last year and felt that it would work out for us,” says Benning.

The Bennings use Flexi-Coil drills with 12 inch row spacings. A Flexi-Coil Stealth single shoot opener delivers the seed and starter fertilizer to the seedrow. Intra-row banders apply anhydrous ammonia mid-row. He also uses a GPS Outback and AgLeader PF3000 monitor. A Raven SCS 440 and Dickey John Land Manager are used for auto rate controllers for the anhydrous ammonia.

Like Slimmon, fertilizer rates were cut back in areas of low yield potential, and increased in areas of high yield potential. Rates ranged from 20 to 135 pounds actual N. Unfortunately, Benning also suffered through a hot July, cutting back on yield. However, he does believe that he still made money through a combination of fertilizer

savings and increased yield over a flat rate application.

Looking at one field from Benning’s 2007 economic analysis, the 308 acre field had a yield target of 40bu/ac of canola. On that field, the InSite VRN program recommended an overall savings of 19lb/ac of N, for a savings of $8.78 per acre. The program also called for higher revenue from increased yield of $49.73 per acre, for a total advantage of $58.52 per acre or $18,000 for the field.

While Benning says the dry weather cut into those increased returns, he still maintains the variable rate application was worthwhile. “We’re going to do all the land except the pulses in 2008. It just makes sense to me,” he explains.

Surprisingly, neither Benning nor Slimmon believe that their land is particularly variable in the traditional sense. No rolling pothole country, rather, differences in salinity, soil type and organic matter provide the greatest variability.

Staples recommends using combine yield maps to verify both the land management zones, and also to provide feedback on actual yields in those management zones. These can then be compared back to the theoretical yield maps to see how well the InSite VRN program performed.