Features

Agronomy

Corn

Slow down seeding: reap rewards from emergence to harvest

Ed Rempel of Starbuck, Manitoba has found slowing down to seed canola pays off, even though he often has a very narrow seeding window on his heavy clay in the Red River Valley.

March 3, 2009 By Helen McMenamin

Ed Rempel of Starbuck, Manitoba has found slowing down to seed canola pays off, even though he often has a very narrow seeding window on his heavy clay in the Red River Valley.

|

|

| Determining seeding speed is a cost/benefit analysis. Photo courtesy of Bruce Barker. |

“I slow down to 5 mph for canola, compared to 5.6 or 5.7 mph for cereals,” he says. “I probably should go down to 4.5, but that’s too stressful. I slow down till the machinery stops bouncing around and rides quieter. That means more even depth control and better emergence.”

Better depth control allows Rempel to use a little less air and possibly cut seed rates a little. He has not seen a yield benefit but he has seen benefits in the effectiveness of fungicides. “Fungicides should be applied at 20 percent bloom,” he says. “A more even crop means most of the plants can be at that optimum stage so I can get better disease protection, and more value from those very expensive chemicals.”

Giving in to the temptation to seed as many acres as possible during the seeding window can mean a grower might pay all through the season and at the bin. All crops need good seed placement and seed-to-soil contact, but for small seeded crops like canola, this is even more critical. “Slow down,” says Canola Council agronomist, Doug Moisey. “Seeding at the optimum speed for your soil conditions and equipment can prevent yield losses of 20 percent or more due to uneven stands. Remember, direct seeding means making your seedbed as you seed. Do whatever it takes to create a good one. If you’re not putting all the seed at the correct depth with good seed-to-soil contact, slowing down could make a big difference.”

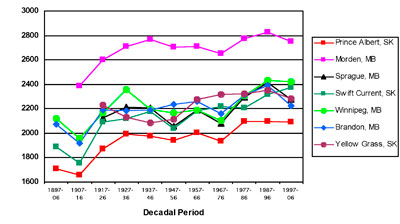

Moisey cites research he did at the Canola Council of Canada that compared the range and uniformity of seed placement at different speeds. Not only did average depth increase, but so did variability of seed placement.

Newer precision drills maintain depth control at high speed, but most seeding equipment is less accurate at faster speeds. Often, the implement bounces more, or tips as speed increases so that each rank of openers is at a different depth, leaving some seed on the soil surface and some buried too deep. With some seeders the openers throw soil on top of seed placed by the front openers, effectively seeding it deeper.

Seed placed at three depths means emergence in three waves. Not only do the seedlings have to grow through more soil, deeper soil is also colder, which further slows germination and emergence. The emerging seedlings are also subject to more stress from seedling diseases and insects. “Spreading emergence over a few days is fine,” Moisey says. “But five or six days added to the spread between knolls and bottoms can be too much of a spread. I’ve seen emergence spread over three weeks; the late-emerging plants never catch up.”

Slow emergence over many days also leaves the crop more vulnerable to pests like flea beetles.

Uniformity rules

Management decisions are much easier with an even stand. As Rempel points out, timing of spraying is more difficult in a field with plants at several stages. Later in the season, an uneven crop blooms longer and maturity is uneven, making it virtually impossible to choose the ideal time for swathing.

|

|

| Effect of seeding speed on seed depth Canola Council of Canada |

Other factors also come in to play with accurate seed placement. Moisey advises farmers to double-check trash management, and he strongly advises waiting until soil temperatures at seeding depth average four or five degrees C before seeding canola. Determine temperature by averaging the temperatures at seeding depth in the early mornings and afternoons during three days. If seeding early into cold soils is necessary, do not chase moisture, and place seed between one-half and one-inch below the press wheel furrow. “Level the seeder front to back as well as side to side. Calibrate the seeder at the speed you plan to seed,” says Moisey.

Shallow seeding also requires an optimum seed to ensure that soil flows smoothly around the opener to close the furrow and pack soil over the seed. Faster travel can break up the flow of soil and either leave the seed buried too deeply, or not at all.

Also, at faster speeds, delivering the right amount of seed to the opener often takes a higher fan speed that can lead to seed damage. Moisey recommends checking seed delivery with “tube-sock technology.” Unhook the seed delivery tube from the opener at the end of the drill and tape a sock to it. Seed for a set distance, then check the weight of seed and look for seed damage. If cracks and splits are visible, it is likely there is significant damage that will affect seed performance.

Increasing the wind to deliver more product can also increase seed bounce, resulting in the seed rolling out of the row or into the fertilizer trench.

Moisey advises checking seeding performance regularly and walking about 150 yards back from the tractor each time. “You want to check your seeding job where you’re running at field speed. And, don’t assume things are fine because you find some seed at the right depth. Check above and below your intended seeding depth, in the fertilizer trench and in several rows across the width of your seeder. Variations in soil conditions can affect seed placement, so check in typical areas, not on headlands.

Double checking accuracy

Moisey suggests two checks on seeding accuracy. Count plants per square foot in last year’s canola stubble. If plant numbers are outside the ideal of eight to 14 per square foot, modifying seeding practices could boost yields.

He also suggests a five minute test: seed at the usual speed, drop it by 0.5 mph, and then another 0.5 mph. Then try seeding 0.5 mph above standard seeding speed. Differences due to seeding speed can be quite obvious in the field.

While every farmer will have to reach a compromise on the timeliness of seeding and the speed he seeds at, the guiding principle should be to assess seedling emergence and uniformity. If one or the other is out of whack, chances are, seeding speed may have to be adjusted.