Features

Agronomy

Other Crops

Aerial fungicide control in chickpeas can work

Aerial and ground fungicide applications work equally well for ascochyta control in chickpea.

November 27, 2007 By Bruce Barker

Fungicide application is an important disease management strategy in chickpea

production. Left untreated, ascochyta can cause yield losses over 90 percent

in Saskatchewan, so appropriate timing and frequency of fungicide application

is critical. That makes aerial application ideal, since fungicides can be efficiently

applied without tracking in the crop. But aerial brings a disadvantage of less

water volume per acre, which may result in less leaf coverage with the spray.

|

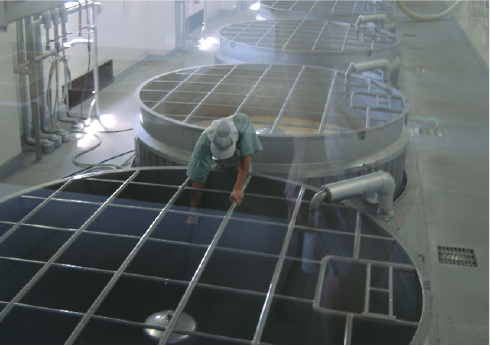

| Advanced stage showing ascochyta lesion. |

"The relative importance of these characteristics were unknown,"

says research scientist, Tom Wolf with Agriculture and Agri-Food Canada (AAFC)

at Saskatoon. "We wanted to find out if ground or aerial brought greater

advantages in disease control, yield and seed quality."

Wolf was part of a research project that looked at Ascochyta rabiei

control with aerial and ground application equipment near Saskatoon in 2003

and 2004. Each year, about 30 acres was seeded to CDC Xena kabuli-type chickpeas.

At the first sign of disease, applications of fungicide were commenced and maintained

at approximately 10 day intervals. In 2003, four applications, two with Headline

and two with Lance were conducted. In 2004, the last Lance application was not

done.

Aerial application was made using a Cessna AgTruck applying 37L/ha (3.33gal/ac)

using CP-03 nozzles with the 0.125 flow orifice and 90 degree deflection, at

a pressure of 234kPa and 192km/h air speed. The spray had a volume median diameter

(VMD) of approximately 271µm. Boom height was three to 4.5 metres above

ground.

Ground applications were conducted using a Melroe SpraCoupe travelling at 13km/h

applying 100L/ha (9gal/ac) using XR8003 nozzles operated at 275kPa and a boom

height of approximately 75cm – with a VMD of approximately 246µm.

Disease symptoms were evident in early July in both years, and ratings were

done throughout the season. Seed yields were taken at crop maturity.

Disease incidence progressed to 80 to 90 percent in the untreated plots, and

fungicide application reduced disease incidence to 20 to 30 percent and increased

seed yield in both years.

| Figure 1. Ascochyta blight incidence on chickpeas throughout the growing season, 2003 (left) and 2004 (right). Source: Wolf, AAFC Saskatoon. |

|

Aerial and ground both held back ascochyta

In both years, disease incidence and seed yield were not affected by application

method. In 2003, disease in the untreated chickpea quickly progressed from about

five percent to about 66 percent from July 9 to July 31. A late flush of disease

on new growth increased levels to 87 percent on untreated chickpea. On the treated

chickpea, disease incidence on ground and aerial treatments was 18 and 21 percent

on July 31 and 28 and 41 percent on August 14.

In 2004, untreated plots ended up with 99 percent infection on September 14,

while ground and aerial plots ended up with similar infection levels of 18 to

20 percent.

Spray deposits analyzed

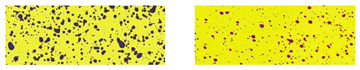

Wolf also looked at spray deposits from both application methods. He used water-sensitive

cards and found that the ground application had greater overall coverage, primarily

because of greater water volume (9gal/ac for ground vs. 3.33gal/ac for aerial).

The ground application covered a greater area of the water-sensitive cards,

compared to aerial application.

"The most important application parameter for aerial spraying is water

volume," explains Wolf. "All other things being equal, there is no

substitute for greater water volume."

| Figure 2. Spray deposit on water-sensitive paper for ground application at 100L/ha (left) and aerial application at 37L/ha (right). Source: Wolf, AAFC Saskatoon. |

|

The difficulty in achieving good coverage with aerial fungicide applications

is the fine balance between water volume, droplet size and spray drift. Smaller

droplets mean better coverage, but greater drift. Larger droplets mean lower

drift, but less leaf coverage unless water volume is increased, but increased

water volume means lower productivity.

"Most fungicides require four US gal/ac (3.33 Imperial gal/ac) of water

and the Headline label recommends five US gal/ac (4.4 Imperial gal/ac). That's

in recognition that you need good coverage of the plant to control diseases,"

says Wolf.

Wolf did not measure uniformity of the spray pattern across the width of the

boom or spray swath for either ground or aerial application. He says ground

sprayers can provide a very uniform spray across the width, but uniformity is

more difficult with aerial applications.

"The difficulty with aerial applications is that you have to deal with

aerodynamics. You can get turbulence from wheels, propellers and even the boom,"

explains Wolf. "Imagine if your spray pattern has 50 percent more in some

areas and 50 percent less in others. That could have a real influence on control

with fungicides."

In this research, Wolf did not see any uniformity issues, but he points out

that the crop was sprayed four times in 2004 and three times in 2003. That may

have helped with control if uniformity across the spray width was an issue.

He says that with a single application, spray swath uniformity may be more critical.

"Aerial applicators know the importance of obtaining uniformity across

the width of the spray swath and they do as much as they can to make it uniform,"

says Wolf.

|

| Early ascochyta lesion on chickpea. Photos Courtesy Of Tom Wolf, AAFC. |

Yields similar, but wheel tracks caused losses

Fungicide applications increased yields in both years. In 2003, yield averaged

13bu/ac for the unsprayed treatments and 33bu/ac where fungicides had been applied.

Aerial treatments yielded 32.7bu/ac. Wolf adjusted the ground treatment yield

to take wheel track damage into consideration, and equated the yield to a sprayer

with a 90 foot boom width. This track adjusted yield was 34.4bu/ac in 2003.

This difference was not statistically significant between aerial and ground.

Ground-sprayed areas without wheel tracks yielded 36bu/ac, so yield loss due

to tracks was 1.6bu/ac.

Seed yield and quality results for 2004 were greatly reduced due to cool weather

and an early frost. However, the results mirrored the 2003 trends.

One common concern, that Wolf did not observe, is wheels tracking disease around

the field. "I have heard of anecdotal reports that wheels can spread the

disease if the crop is wet, or even walking through a wet field while scouting

may spread the disease," says Wolf. "We didn't see that, but that

may have been due to the dry field conditions when we applied the fungicides."

Penny Pearse, provincial disease specialist with Saskatchewan Agriculture and

Food at Regina, says that ascochyta can indeed be spread throughout a field,

or between fields, by sprayers, or by crop scouts. "I've even seen tracks

from wildlife such as deer moving disease through a field," says Pearse.

She says that disease tends to spread when the crop is wet because the spores

can be carried in water droplets. Furthermore, breakage of stems by tires or

other movement through the field causes wounding, which opens the plant up for

infection.

"Our general recommendation for farmers and agrologists is avoid spraying

after a rainfall or when the crop canopy is damp, if possible," explains

Pearse. "And if you are crop scouting, scout when the crop is dry, or change

pants and boots between fields, or start with fields that are disease-free before

moving to a diseased field. Still, the benefit of scouting and spraying crops

far outweighs the risk of potential disease spread."

Judging by the results of Wolf's research, neither ground nor aerial bring

a definitive advantage over the other. Ground application brings the benefits

of thorough coverage, low drift and uniform application, but at the expense

of wheel track damage, slower application times and the potential for spreading

disease if the crop is wet. Aerial application can quickly get the job done,

but with a greater degree of difficulty in managing spray drift and spray quality.

However, with similar yield responses, the results do show that farmers should

not be afraid of using either, as long as they are aware of the risks and benefits.