Features

Fertilizer

Seed & Chemical

World fertilizer nutrient reserves: a view to the future

The stewardship responsibilities of agriculture include the wise use of the raw materials from which commercial fertilizers are produced. Development and implementation of fertilizer best management practices (BMPs) with focus on the “Four Rs” – right source, right rate, right time, right place – are timely not only for short-term economic and environmental reasons, but also for the wise stewardship of the non-renewable nutrient resources upon which food, feed, fibre and fuel production depend.

February 24, 2010 By Dr. Paul E. Fixen*

|

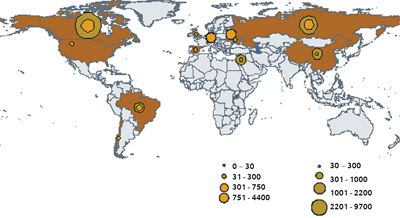

| Figure 1. Economic and potentially economic phosphate deposits of the world

|

The stewardship responsibilities of agriculture include the wise use of the raw materials from which commercial fertilizers are produced. Development and implementation of fertilizer best management practices (BMPs) with focus on the “Four Rs” – right source, right rate, right time, right place – are timely not only for short-term economic and environmental reasons, but also for the wise stewardship of the non-renewable nutrient resources upon which food, feed, fibre and fuel production depend.

The extreme spike in N, P, K and S fertilizer prices midway through 2008 sent shock waves around the world. Some pondered whether fertilizer nutrient reserves were reaching critically low levels and contributing to market volatility. This paper will attempt to review the status of world nutrient reserves in terms of current production.

|

| Figure 2. World phosphate rock production, 1981-2008. For 1992-1997, former Soviet Union includes Kazakhstan and Russia data; afterwards, only Russia.

|

Phosphate

The main raw material used in the production of nearly all phosphate fertilizers is phosphate rock (PR). There are two general types of PRs, igneous and sedimentary. Insular or island deposits are a special type of sedimentary deposit. Figure 1 shows a map of PR deposits currently being mined, those that have been mined in the recent past, and those that have been shown to be potentially economic (McClellan and Van Kauwenbergh, 2004). They are widespread throughout most of the world.

Igneous PRs typically contain apatite as the P form along with other igneous minerals. Igneous deposits often yield low grade ores, but can be beneficiated to higher grades in the range of 36 to 40 percent P2O5 (Stewart et al., 2005). Ores from igneous deposits are relatively unreactive. Consequently, they are not well suited for direct application to cropland and typically must be finely ground for use in fertilizer processing.

About 80 percent of the PR produced in the world is from sedimentary deposits. These deposits vary markedly in both physical and chemical properties, ranging from loose, unconsolidated materials to hardened rocks and from fluorapatite with almost no carbonate substitution to six to seven percent carbonate for phosphate substitution (Stewart et al., 2005).

World PR production since 1981 has been generally rather flat overall, ranging from 120 to 165 million tonnes per year (Figure 2). However, the breakup of the Soviet Union caused a substantial disruption in phosphate production, resulting in major declines in the early 1990s. World production has just recently climbed back up to pre-breakup levels exceeding 160 tonnes. China has been the major source of production increases during the last 20 years.

Estimation of PR reserves and resources is plagued with uncertainty due to limited information to assure accuracy of the estimates. Phosphate producers often consider reserve information to be confidential, leaving publicly available scientific papers and specific deposit reports as the primary information sources. Therefore, the reserve information presented here needs to be viewed as general approximations with broad confidence intervals.

|

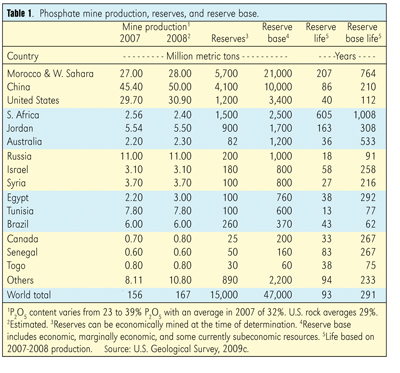

Table 1 contains current estimates of world PR reserves and reserve base sorted by reserve base tonnage. Reserves and reserve base terms are defined by the US Geological Survey (USGS) as follows. “Reserves, that part of the reserve base which could be economically extracted or produced at the time of determination. The term reserves need not signify that extraction facilities are in place and operative. Reserve base, includes those resources that are currently economic (reserves), marginally economic, and some of those that are currently sub-economic.”

However, personal communication with USGS indicated that current reserve estimates are based on market conditions from at least a few years ago and so do not reflect 2008 prices. Therefore, the portion of reserve base tonnage reported as reserves may be underestimated.

Morocco and Western Sahara are reported to have the largest PR reserve base and reserves in the world, accounting for 45 percent of the world reserve base (Table 1). China follows with 21 percent of the reserve base, so these two countries have two-thirds of the world RP reserve base. Table 1 also contains estimates of PR reserve life and reserve base life based on the average production of 2007 and 2008. At these production levels, world PR reserve and reserve base longevity would be estimated to be 93 and 291 years, respectively.

At this point, it is critical to remember the earlier comments about the reliability of these estimates. Two examples illustrate this point. First, in 2002, USGS was estimating PR world reserves and reserve base at 12,990 and 46,990 tonnes respectively (Stewart et al., 2005). The 2009 estimates discussed above represent 122 percent and 100 percent of these earlier estimates, even though an additional 7 years of production has occurred since they were made. As a second example, Sheldon (1987) reported world PR reserves at 15,259 tonnes (about the same as is being estimated today) and identified resources (reserve base plus inferred reserve base) as 112,431 tonnes. These identified resources based on today’s production would amount to longevity of 696 years.

Clearly, great uncertainty exists in these estimates. And just as clearly, the world is not on the verge of running out of raw materials for phosphate fertilizer production. That said, these are non-renewable natural resources and deserve our very best stewardship.

Potash

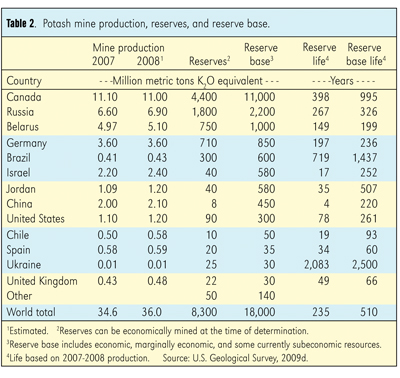

Potash refers to a variety of K-bearing minerals with the most common ones being sylvite (KCl), sylvinite (KCl+NaCl), hartsalz (ore deposits with sulphate salts) and langbeinite (K2SO4 • 2MgSO4). Economic sources occur in sedimentary salt beds remaining from ancient inland seas (evaporate deposits) or in salt lakes and natural brines. The world’s largest reserves occur in Saskatchewan, Canada, where the ore is exceptionally high grade (25 to 30 percent K2O) and occurs at depths of 1000 metres up to greater than 3500 metres. These deposits are mostly sylvinite, with some carnallite (KCl•MgCl2•6H2O) and clay.

|

Production, reserves, reserve life and longevity based on USGS data are reported by country in Table 2 Canada has 53 percent of world potash reserves while Canada, Russia, Belarus, and Germany collectively have 92 percent. World potash reserves are huge, with a reported reserve life based on current production of 235 years and a reserve base exceeding 500 years.

New production of about one tonne of K2O capacity is expected to be added per year from 2009 through 2011, mostly by Canada, Russia and Israel, with some from Jordan and the US. An additional five tonnes is expected in 2012 by Canada, Argentina, Belarus and Jordan (Prud’homme, 2008). New production through 2012 would total approximately

eight tonnes.

|

| Responsible use of fertilizer is in the best interests of all producers, despite large world supply of N, P, K and S.

Photo by Ralph Pearce.

|

Sulphur

Sulphur is one of the more common constituents of the Earth’s crust. USGS estimates resources of elemental S in evaporate and volcanic deposits and S associated with natural gas, petroleum, tar sands and metal sulphides at about five billion tons. The S in gypsum and anhydrite is almost limitless, and some 600 billion tons of S is contained in coal, oil shale, and shale rich in organic matter. But low-cost methods have not been developed to recover S from these sources (USGS, 2009e).

However, S is not generally produced intentionally as a primary product. Most of the S available on the world market today is extracted from natural gas and oil as crude oil contains from 0.1 to 2.8 percent S (IFDC, 2008). Some S is also recovered from coal, the roasting of sulphides in metallurgical processing, and by mining of pyrites.

About 80 to 85 percent of the world’s S production is used to manufacture sulphuric acid. Half of the world’s sulphuric acid production is used in fertilizer production, mainly to convert phosphates to water-soluble forms. About one ton of S is needed to produce a little more than two tons of diammonium phosphate (DAP) (IFDC, 2008).

The leading countries in S production are the US, Canada, China and Russia. These four countries produce almost half of the world’s S. Because petroleum and sulphide ores can be processed long distances from where they are produced, USGS points out that actual S production may not be in the country for which reserves are attributed. This is one of the reasons that reserves and reserve base data are not reported by country for S. Gypsum (CaSO4•2H2O) production is reported by country. A small amount of this product is used for agricultural purposes as a soil conditioner and a nutrient source. As an example, a little more than one tonne of the 12.7 tonnes of gypsum produced in the US in 2008 was used in agriculture. In the long-term, the increase in world S supply is expected to overcome spot shortages as occurred in mid-2008 when S prices skyrocketed from less than $100/ton to more than $800/ton. The price spike was driven by tight supplies resulting from lower than expected production in the US and slow progress at new petroleum and natural gas developments, coupled with increased consumption at phosphate fertilizer operations. A sharp decline in S demand in Asia in the third quarter of 2008 drove the price crash that occurred late in the year.

Nitrogen

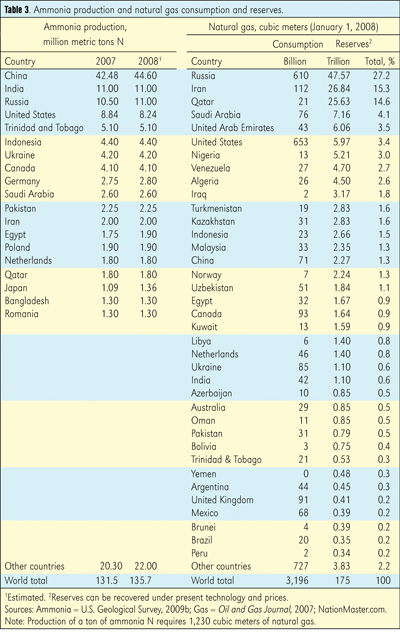

Ammonia (NH3) is the basic N source used in the manufacture of most N fertilizers. About three percent is used in direct application to crop land, mostly in North America. Non-fertilizer use accounts for about 16 percent of world NH3 production (Abram and Forster, 2005). China, India, Russia and the US account for more than 50 percent of total current NH3 production, with China alone contributing nearly one-third of total production (Table 3).

|

Natural gas (CH4) is the feedstock used in 75 to 80 percent of ammonia manufacturing (Abram and Forster, 2005) worldwide with about 1230 cubic metres of gas required per ton of ammonia N (Huang, 2007). However, NH3 manufacturing is a very small consumer of natural gas in most countries. Even if one assumes that all NH3 is produced from natural gas, five percent of annual world gas consumption would be used for NH3 production. In the United States, only about 1.5 percent of natural gas goes to NH3 synthesis.

Thus, natural gas prices are generally independent of fertilizer markets, but greatly influence where fertilizers are manufactured. Rising natural gas prices in developed countries are causing a shift of N production to developing countries. Several companies have announced plans to build new ammonia plants in Algeria, China, Libya and Peru (USGS, 2009b).

The topic of reserves for N fertilizers, considering the dominant manufacturing processes in use today, essentially becomes a discussion of natural gas reserves. Gas consumption and reserves sorted by reserve quantity are reported in Table 3. Russia, Iran, and Qatar have 57 percent of proven world gas reserves. Globally, we are consuming about 3.2 trillion cubic metres of gas per year and report 175 trillion cubic metres of proven reserves, giving longevity of 55 years. However, world natural gas reserves have generally trended upward, indicating that thus far producers have been able to continue replenishing reserves with new resources over time (Energy Information Administration, 2008). The largest recent additions to natural gas reserve estimates were reported for Venezuela and Saudi Arabia.

Summary

World reserves and resources for N, P, K and S appear adequate for the foreseeable future. However, nutrient costs will likely rise over time as the most easily extracted materials are consumed. Therefore, an added incentive for continued refinement and implementation of fertilizer BMPs is that the resulting gain in efficiency will slow the increase in fertilizer costs. Wise stewardship of non-renewable nutrient resources is a critical responsibility for the agriculture industry. n

*Dr. Paul E. Fixen is senior vice-president, Americas Group co-ordinator and director of research with the International Plant Nutrition Institute in Brookings, South Dakota. Reprinted from Better Crops with Plant Food, with permission of International Plant Nutrition Institute (IPNI).