Sprayers

Understanding spray nozzle technology

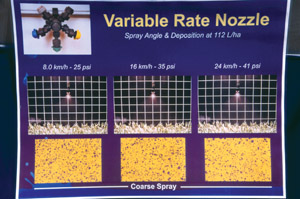

No ‘right’ nozzle, certainly some wrong nozzles, but the new variable rate nozzles may turn out to be the breakthrough.

April 8, 2008 By Bruce Barker

Where to start when choosing a spray nozzle? It has to address spray drift concerns while still delivering a droplet size that produces optimum pesticide performance. And with an ever-changing line-up of nozzles on the market, applicators are left wondering which nozzle to choose.

|

| The VariTarget nozzle achieves uniform spray patterns over a wide range of operating conditions. |

“Before we started our extensive research on spray nozzles, I thought that a right spray nozzle or technology was out there. Now, I think things are more complicated than that, and that rather than the right technology, several nozzles may be capable of handling most applications,” says Brian Storozynsky, a project manager at the AgTech Centre in Lethbridge, Alberta. Since the development of variable rate nozzle technology, he has revised his opinion and now thinks that variable rate nozzles might be the one technology to cover most application scenarios.

Tom Wolf, a researcher at Agriculture and Agri-Food Canada (AAFC) at Saskatoon, Saskatchewan, has worked on nozzle research, as well. He says applicators want to use low water volume to save time, and low drift nozzles can reduce drift, but the challenge is to find out if the two can be used together.

“Most sprayers now operate with a rate controller and when you change travel speed, you change the flow rate to the boom. When you slow down, there is less flow and when you speed up, there is a higher flow. That can change both droplet size and pattern of the spray,” explains Wolf. “The question that needs to be answered is where does performance start to drop off?”

When water volume is kept constant, then the coarser the spray, the fewer number of droplets it will contain. If the droplet size is kept constant but less water is applied, there will be fewer droplets. And if the applicator increases droplet size and decreases water, the result may be incomplete coverage and poor pesticide performance. However, somewhere in the middle is the Goldilocks ‘just right’ approach.

Many options

The old 80 or 110 degree flat fan nozzle was the standard for field sprayers for many years and worked well behind most pull-behind field sprayers operating within a standard range and a standard ground speed. When automatic rate controllers were introduced more than 20 years ago, performance with these nozzles fell.

The next evolution in flat fan nozzles was the extended range type, which allowed for variable flow rates to compensate for changing field speeds. Unfortunately, Storozynsky says these nozzles had a finer spray and spray drift jumped up to 20 percent under normal operating conditions. “There were large drift problems, and I don’t think there is a need for using extended range 110 degree nozzles for most field sprayers,” says Storozynsky.

Next up on the market was the wide angle Turbo TeeJet nozzle, which became the workhorse nozzle in the 1990s. Still, it had eight to 10 percent drift, which was better than the

extended range nozzles, but still presented a drift concern.

In the mid 1990s, the venturi air induction nozzle came on the market. These have an internal orifice that regulates flow and an exit flat fan nozzle that shapes the spray. Air is also sucked into the nozzle body and mixed with the spray solution before exiting the nozzle. This creates air bubbles inside the liquid spray droplets. As a result, the droplets are larger and Storozynsky has found that spray drift is lower. Some manufacturers claim the air bubbles help the droplets shatter on impact, increasing leaf coverage despite the larger initial droplet size.

Venturi air induction nozzles are generally classified into two groups. Low pressure nozzles operate in the 20psi to 70psi range, while high pressure nozzles operate from 40psi upwards to 120psi. Storozynsky has found that the low pressure group has drift around four to five percent and the high pressure, with its coarse droplets, has drift below two percent. He says that each manufacturer’s nozzle produces a different spray characteristic when it comes to coverage, droplet size and drift. However, he has found the high pressure nozzles work the best at a pressure of 80psi.

|

| Brian Storoznysky says balancing droplet size and spray drift has been difficult. |

“Where the venturi air induction nozzles cause concern is with the coverage,” says Storozynsky. “In our studies over the last seven years, we found that under some field conditions like high operating speeds in which low water volumes tend to be used with large sized nozzles, the droplets could be too coarse.”

Wolf has also seen reduced coverage and declining weed control when droplet size gets too coarse. He has found that very coarse sprays should be avoided with Group 1 products used for wild oats control. Low drift coarse sprays are an effective tool for reducing drift and widening the window of opportunity for spraying in marginal wind conditions. However, he says they must be used cautiously with low water volumes and grassy weeds.

In his research, Wolf found that at low water volumes, medium sprays or finer should be used for grassy weed control. At 7.6gpa (85L/ha) or higher water volumes, coarse sprays can be used without compromising grassy weed control. However, he cautions that grassy weeds should not be sprayed below 4.5gpa (50L/ha).

New variable rate nozzle technology might be the answer

Wolf says a new technology that controls flow rate at each nozzle has hit the market in the last few years. While traditional systems with a single-sized nozzle orifice rely entirely on pressure to change flow, the new systems use solenoids or spring-loaded valves to increase flow when the rate controller demands it. As a result, there is less fluctuation in pressure and greater consistency in droplet size and spray pattern uniformity when travel speeds fluctuate. However, he cautions that for some of these there is not yet a lot of research available to support pesticide effectiveness.

Three manufacturers now have these variable rate nozzles. The AIM Command Spray System, utilizing Capstan technology that was once available only on Case IH sprayers, is now available as an aftermarket retrofit (Capstan Sharpshooter) for sprayers other than CNH. It is the most mature, with 10 years and more than 1500 units in the field. With this system, each nozzle has an electronic pulsing solenoid that controls flow rate. For example, if the sprayer travels faster, the flow rate can be increased without changing pressure. This system is proven in both research trials and by end users.

Delavan Agspray Products produces the VariTarget nozzle. This nozzle uses a spring-loaded valve to control flow rate in response to pressure changes. Wolf says the nozzle has good response to changes in travel speed and that the effect on droplet size is negligible. In this system, doubling the pressure doubles the flow rate, whereas a conventional nozzle would only achieve a 40 percent increase in flow. The VariTarget nozzle comes with four nozzle caps to spray fine, medium, coarse or very coarse spray droplets.

The third variable rate nozzle is from Greenleaf Technologies and is called the TurboDrop Variable Rate (TDVR) nozzle. It uses a similar spring-loaded valve that adds flow volume in response to higher pressure, making the flow response directly proportional to pressure changes.

Of the three variable rate nozzle types, the VariTarget concept, in Storozynsky’s opinion, addresses issues that plagued operators since the inception of auto rate controllers in the early 1980s. “Finally, after 25 years, a nozzle that is truly compatible with rate controllers,” he says. “Spraying speeds can be adjusted by more than just two miles per hour without worrying about inadequate coverage at low pressures or drift at high pressures.”

|

| The green (very coarse) VariTarget nozzle. Photos By Bruce Barker. |

Storozynsky gives an example how the VariTarget works. With an auto rate controller programmed to apply 10gpa at 10mph, an operator can slow down to 3.5mph or speed up to 20mph with coverage and droplet size remaining very similar over that range. Compared with conventional nozzles at the same application rate, speeds between 7.5mph and 12.5mph could be used only before operating outside the recommended pressure range of 20psi and 60psi.

VariTarget’s variable area pre-orifice and spray orifice was of primary concern prior to testing the nozzles, says Storozynsky. As changes in spraying speed or application rate occur, VariTarget spring-loaded plunger slides between a wedge inside the nozzle cap to change pre-orifice area (flow) and shape of the spray orifice to maintain spray fan angle. However, tests showed both orifices performed very well and spray coverage and pattern tests were consistent. Flow rate variability among nozzles was around three to six percent compared to conventional nozzles that are at two to three percent.

Durability of the nozzle caps spray orifice was another concern. Would the variable area spray orifice remain flexible after extensive use? Storozynsky says several farmers have reported spraying more than 100,000 acres with VariTarget nozzles without replacements. “Growers may finally be able to do most of their spraying with one nozzle,” he says. “How much easier can it get? It’s not perfect; some coverage problems exist especially at low nozzle flow rates and pressures, but it is close,” says Storozynsky.

Wolf also believes the variable rate nozzles may be the answer for applicators who are struggling with drift and coverage issues. However, he cautions growers that not a lot of research has been done on them yet. “The theory behind the VariTarget and Greenleaf TDVR is good, but there is very little research in the scientific community at this point, so it is buyer beware,” says Wolf.

The new variable rate nozzles are costly, at $42 to $49 range per nozzle for the VariTarget nozzles. At a nozzle spacing of 20 inches, that would cost $2650 for 54 nozzles on a 90 foot boom. Storozynsky says that may be a small price to pay for accurate and effective pesticide application.

“Has not the spraying industry progressed adequately that nozzles should now be treated the same as any other agricultural input?” he asks. “We pay $2500 to spray 160 acres yet complain about the price of a nozzle that will spray tens of thousands of acres accurately and safely.” -end-