Features

Agronomy

Cereals

Unconventional methods, uncommon results

Grower steers clear of corn into wheat.

February 16, 2008 By Ralph Pearce

For some growers, the key question they ask in a situation is not ‘Why?’ but ‘Why not?’ For Paul Kernohan, the answer is better yields, less compaction and a cropping system with which he is the most comfortable.

Kernohan works nearly 3000 acres outside of Forest, Ontario, along with three partners; his son Chris, Gary Huctworth and Gerald Spruyt. For much of the past 12 years, he has rotated his corn into soybean ground instead of spring planting into wheat stubble, “which is just contrary to my way of thinking now,” he says, noting soybeans as his largest crop in terms of acreage.

|

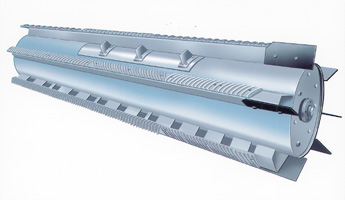

| Disc ripping wheat stubble in the fall is part of the management system used by Paul Kernohan, who favours rotating his corn into soybean ground. |

“In order to get a a reasonable rotation, I rotate wheat and corn ground into beans every year. We’re getting better yields with less cost following soybeans with corn than we would with wheat because the residual nitrogen in the soybeans gives corn a good start. The other cost saver is we don’t touch the bean stubble until spring, thus saving one or two trips with the equipment. Wheat stubble is disc ripped in the fall once and left as mulch. Usually one finishing trip ahead of the planter is enough.”

The other benefit for planting corn in soybeans is that the ground is normally drier in the early spring than wheat ground, translating into less compaction. The regimen does nothing to delay his planting date; he can go as early as any other grower planting corn to wheat stubble, although for Kernohan, later planting is as much a comfort zone issue as it is agronomic.

The results he is getting are enough to keep him and his partners on the same course, year after year. In a dry 2007, his corn yields were 165bu/ac to 220bu/ac where there were timely rains. “We have some land over a road to the north that missed the middle rains when we had three good rains here, but the fields on the road north saw a reduction of 20bu/ac to 30bu/ac on the corn and about a 10bu/ac reduction on the soybeans,” explains Kernohan. A cousin of his who received similar amounts of moisture was 10bu/ac to 15bu/ac behind on yield. “He disc ripped his wheat stubble in 2006 and he had a good yield, but I was that much ahead of him in 2007.”

Less compaction a huge plus

In the years he has been doing things ‘backwards’, Kernohan has reduced his tillage and compaction has lessened, as well. “We needed a little better and quicker rotation, but then I noticed that as the equipment got bigger, the headlands got worse, especially new corn on wheat ground, and especially when plowed,” details Kernohan. “I plowed 30 acres of very wet wheat stubble in 2006 and quit before finishing the field. The disc ripper was brought out to to finish.”

Prior to that, Kernohan noticed several growers in his area plowing wheat stubble, then having compaction problems, particularly on their headlands. However, he does not have that problem. “Our headlands are just as good as the interior of the field,” says Kernohan, who also wonders if there may be better disease control with this system. “We had comments when we did a test plot and there wasn’t a stalk down in the whole plot, and that included Bt hybrids. It’s different and it is backwards to a lot of thinking, but I am starting to get a few converts in my area.”

|

| Bob Thirlwall believes the right attitude is important when trying different management practices; it works for a grower because the grower makes it work. |

Kernohan notes there have been quite a few side-by-side comparisons of plow versus disc rippers, with varying results. But he adds that a grower must be ready to work that ground differently, as the disc ripper will dry out at least a day earlier. If the test is held until the plowed ground is right, the earlier ground will be too dry, thus creating a drier environment that can affect evenness of germination.”

Benefits of rotation are evident

Rotations and the subsequent success they can bring often lead to more questions: How much can conventional methods be tinkered with? Kernohan is not in the habit of trying to win over growers to his way of thinking. This system works because he makes it work, and it provides a sense of comfort, as well as better yields and improved soil health. But he admits the system is not for everyone nor does he try to convince people to adopt his methods.

However, for Bob Thirlwall, field agronomist with Dekalb, the secret may be out: growers need to ensure their rotations are diverse. “Especially in 2007, where it’s been a pretty clear picture of the benefits of a good, solid rotation,” he says. “What separates the average managers from the successful growers, regardless of their operation, is their persistent attention to details. This includes things like rotation and details surrounding planting conditions, planting depth and consistency of spacing. Attention to planting equipment and how particular you are about how that crop goes in the ground can make a big difference to getting the crop off to a great start.”

That certainly speaks to the system that Kernohan uses. And it says something about growers who ‘dare to be different’; often times, it is their attitude that acts as the lynchpin that leads to continued success. Once they begin to work with a system and achieve comfort or success – or both – they stay with it, regardless of what others might say or think. “It’s almost like no-tillers,” says Thirlwall. “The growers who no-till make no-till work. It suits their management style and the number of hours they’re willing to spend on an acre of land.” -end-