Features

Soil Summit 2019

Soil

The nature and role of manure: soil-plant-animal nutrient linkages

Managing manure to get the most out of it as a fertilizer.

June 20, 2019 By Presented by Jeff Schoenau, University of Saskatchewan, at the Soil Management and Sustainability Summit, Feb. 26, 2019, Saskatoon.

Injecting manure meets 4R objectives. Photo by Rick Taillieu.

Injecting manure meets 4R objectives. Photo by Rick Taillieu. Manure is an important resource as a fertilizer. It contains macronutrients and micronutrients. Sometimes we forget about the contributions that manures can make to micronutrient fertility, like copper and zinc for example. And manure is very important as a soil builder, especially solid manures that add a lot of organic matter to the soil.

One of the challenges is that manure is dilute. Liquid hog manure contains anywhere from 0.1 per cent to 0.5 per cent nitrogen by weight; cattle penning manure, 0.5 per cent nitrogen to 1.5 per cent nitrogen by weight. You literally have to apply a few thousand gallons per acre of a liquid effluent or a few tons per acre of solid manure in order to supply an agronomic rate of a nutrient.

Manure is also variable in nature. It tends to be rather heterogeneous and variable in its composition. You need to test it to know what nutrients are in it.

Manure is also a bit restrictive. It typically doesn’t have the optimal balance or ratio of nutrients that crops need. Usually, we hear about too much phosphorus relative to nitrogen compared to the relative amounts that most crops need. Indeed, when manure is applied to meet a nitrogen requirement, we often end up adding more phosphorus than what the crop needs and can take up. But there are also some other balance relationships that are important – carbon-to-nitrogen ratio in solid manures; nitrogen-to-sulphur ratios in liquid manures – that we also need to pay attention to get the best benefit out of those manure nutrients.

I would be remiss if I didn’t also talk about the effects of manure on soil organic matter, structure, and soil tilth. Organic matter in manure helps to bind the particles together, producing stable aggregates and good structure. However, remember that manures contain salts, and sodium salts in particular can have a negative effect on the structure of the soil due to particle dispersion. So adding manure, especially liquid manure that has a high sodium salt content to a poorly drained soil or a soil that already has some salinity issues to begin with isn’t a very good idea.

Adding organic matter to the soil, especially solid manures, will decrease the density of the soil, and increase porosity, water and air permeability. Those are all good for air and water exchange, and root exploration in the soil.

Solid versus liquid manure

We need to look at manure as a fertilizer rather than a waste material. To manage it properly we need to know what’s in it. We need to know how it behaves. And indeed, all manures are not created equal.

Liquid effluents like liquid swine effluent or liquid dairy effluent tend to have high proportions of their nutrient in immediately plant available inorganic forms, contributing to high nutrient availability in the year of application. There’s not a lot of organic matter in liquid manure compared to solid manures. It’s made up mostly of water and inorganic nutrient ions, so it tends to have the biggest benefit in the year of application.

For liquid effluents, we have pretty good models to estimate the release and availability of nutrients. We measure the ammonium ion content and assign that availability as 100 per cent in the year of application. We then estimate that 20 per cent to 30 per cent of the organic N in the liquid manure will be mineralized in the year of application. Combined, liquid manure generally has 50 to 70 per cent available nitrogen compared to commercial urea fertilizer in the year of application.

However, we have observed in our research trials that some liquid manure, particularly liquid swine manure, often doesn’t contain enough available sulphur relative to available nitrogen to meet the sulphur demands of a high-sulphur-demanding crop like canola when grown on a S deficient soil. We have seen significant canola yield response from application of supplemental commercial sulphur fertilizer when liquid swine manure with an available-N-to-available-S ratio of 12:1 or 14:1 was applied to a field with low soil supplies of available S.

In contrast, solid manures have lots of organic matter, but also tend to have slower availability of nutrients because the nutrients that predominate in the organic form have to be released through microbial decomposition, a process termed mineralization. Solid manures are more important as a soil builder over the longer term by improving tilth and slowly increasing the nutrient supplying power of the soil by adding organic matter and increasing mineralization potential. Just like liquid manure, solid manure is also a very important source of phosphorus, potassium, and micronutrients.

The rate of conversion of manure organic nitrogen into the plant-available forms of ammonium and nitrate can be slow, especially for penning manure that contains a lot of straw or wood chips. If we have a high carbon-to-nitrogen ratio, say above 17- or 18-to-1, in the first couple of years after application the release of available inorganic N from penning manures may be only 10 to 20 per cent of the total nitrogen added in the manure. To get the best response out of those other nutrients in cattle manure, you want to consider supplementing with commercial nitrogen fertilizer in the first couple of years.

Both types of manures are effective sources of potassium.

Managing liquid manure

It is desirable to put liquid manures into the ground in order to reduce odour, reduce nutrient loss, and increase recovery. The majority of the liquid manures on the Prairies are injected into the soil. Low-disturbance liquid manure injectors allow us to inject liquid manure into annual crop land or forage stands without a lot of disturbance, compatible with no-till farming systems.

In some of our earlier work on a very nutrient-deficient soil, we injected 5,000 gallons per acre of liquid swine manure. That equated to about 200 pounds of N per acre. In this trial, canola yield went from eight bushels per acre to 38 bushels per acre. Of course the genetic potential of canola has increased greatly, so if we did the same trial today, we might be looking at 60 or 70 bushels per acre. High-nutrient-requiring crops like hybrid canola can make very good use of the nutrients that are being applied as manure to the soil.

An important goal is to use 4R strategies in manure management that will maximize crop utilization of nutrients. Looking at the cumulative recovery of nitrogen by the crop over four years, in this case over a four-year rotational phase with a cereal and an oilseed in rotation, when swine manure was applied at an agronomic rate of 100 pounds of N per acre, which was about three to four thousand gallons per acre per year, recover was 43 per cent. That recovery rate was just about as good as the urea at 50 per cent recovery of applied N at the same agronomic rate.

However when swine manure was applied at an excessive rate of 13,000 gallons per acre per year for four years (400 pounds of N per acre per year for four years), this was much more N than the crop could use and the proportion of added N recovered by the crop fell to 29 per cent. Some of the unused nitrogen remained as nitrate-nitrogen in the soil profile. We followed post harvest soil nitrate in this trial with the high rate of manure added each year for 12 years and during some very wet years at that site, a lot of the nitrate-nitrogen disappeared. Some of it moved down deeper in the soil profile below the root zone, and a lot of it we could not account for and it likely ended up being denitrified and lost. Over-application certainly leads to inefficient use of that nutrient.

In the case of injection of hog manure into grassland, some of our work with PAMI and the Saskatchewan Forage Council showed some very impressive forage growth responses to injection of liquid swine manure. Two rates of 3,300 and 6,600 gallons per acre were applied to a nutrient-deficient crested wheat grass stand. The 3,300-gallon rate had 100 pounds of N, 15 pounds P2O5 and 50 pounds K2O – double it for the 6,600-gallon rate.

With 3,300 gallons per acre of injected liquid swine manure, biomass doubled, and the biomass quadrupled with 6,600 gallons per acre. In the case of the seed yield, there was a tenfold increase in the seed yield. Additionally, those old grass stands were like a nutrient sponge. They sucked up the available nutrients that were applied so there was very little residual inorganic nutrient hanging around in the soil at any time that would be susceptible to loss.

Managing solid manure

Solid cattle manure can be rather more challenging to get into the ground. We were involved in a project with the University of Saskatchewan College of Engineering and the Prairie Agricultural Machinery Institute (PAMI) to look at the potential for injecting solid manure into the soil in bands. We were able to use a prototype unit in some plot work to evaluate the agronomic and environmental performance of subsurface solid manure injection. The front end of the unit that moves manure to the injector tubes worked very well, but it was sometimes challenging to get the solid manure moving uniformly through injector tubes all the way to the disc openers. I would say it’s still got a ways to go in terms of optimizing performance of the technology, but we were able to do some evaluations of its agronomic effects.

When it comes to using cattle manure for fertilizing forage lands where incorporation is not possible, rather than hauling manure out of a pen and surface-applying, I think a much better approach that a lot of farmers are doing these days is in-field feeding and overwintering.

From the standpoint of a nutrient cycling, a 1,400-pound hay bale might have 30 pounds of N, five pounds of P, 25 pounds of K, three pounds of S. When you feed cows out in the field, those four-legged fertilizer factories consume those bales and cycle a lot of the nutrients back into the soil in the field through the urine and the fecal material they excrete. The animal only retains a small proportion of the nutrient that it consumes, with the rest going out the other end onto and into the soil with an improved opportunity to recycle back into the forage crop. When that nutrient deposition occurs in the field, you get a lot better recycling than when that nutrient is deposited in a pen in the yard, because a lot of that nutrient, particularly nitrogen, gets lost in the pen before it gets to the field.

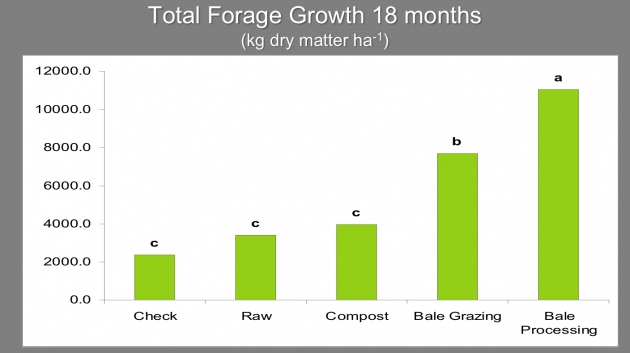

A study was conducted by graduate student, Paul Jungnitsch, working with myself and Bart Lardner out at the Western Beef Development Centre near Lanigan, Sask., that looked at traditional pen feeding versus in-field winter feeding on an old nutrient-deficient Russian wild rye grass pasture. One treatment was hauling manure out of the pen in the yard and applying to the pasture at a rate of 67 tonnes per hectare with a manure spreader. We also had a treatment with applied composted manure at a lower rate (22 tons per ha) to reflect the higher nitrogen content in that compost. Our two in-field feeding treatments were a bale-grazing system where we fed the cattle in the pasture one bale of hay and one bale of straw every three to four days, and a bale-processing system where we fed the processed bales in long rows every three to four days.

In that old Russian wild rye grass pasture, we got a small positive forage yield response from the spread raw and composted manure, but it wasn’t statistically significantly higher than our control. The bale grazing and bale processing treatments gave significantly higher forage growth. Those types of benefits tended to persist beyond the year of treatment. We could still see those areas where the cattle had been fed out in the field two or three years after.

In his work Paul Jungnitsch calculated the nutrient recovery in the forage. This was the capture of nutrients that were added in the feed and bedding and cycled through the animal into manure and taken up by the forage. The in-field systems had fairly impressive recoveries of added nitrogen of 30 to 45 per cent and 21 to 32 per cent P. This compared to only five to nine per cent N, and three to five per cent P when manure was hauled out of the pens and spread onto the pasture. In-field feeding of the cattle had more efficient conservation and recycling of those feed nutrients.

It is very important to choose the in-field overwintering sites carefully to avoid any runoff water entering into sensitive surface water bodies like streams or lakes. In our research work, we found that the concentrations of phosphate and nitrogen are elevated in runoff water moving through that manure pack in the spring. So you want to have that water running into a contained area where you can manage it. There are tools out there that can be used by growers to help effectively select an in-field feeding site to avoid issues. An example is the Wintering Site Assessment and Design Tool: Guide to Selecting and Managing Wintering Sites in Western Canada.

4R manure management

Manure addition using 4R principles – the right source, right time, right place, and right rate – contributes to a positive effect on plant growth and soil quality over the years. Certainly some fine-tuning can improve those responses and economic return. An important finding from our trials is that when you do it right, nutrient loading and escape issues do not appear to be a concern. For example, losses are minimized when manure is applied at ‘agronomic right rates.’ These are rates at which the nutrient that you’re putting in is balanced or matched off by the amount of nutrient that’s leaving the system in crop harvest over the years.

The 4R system applies to both manure and commercial fertilizer. The “right place” is very important for manure. Liquid hog manure injection technology was developed by PAMI back in the early 1990s, and the agronomic advantages of direct injection of liquid hog manure are very well documented.

Our long-term trials with liquid hog manure showed that cumulative nitrogen recovery by the crop over a number of years where the manure was injected into the soil in bands was 43 per cent versus 31 per cent when it’s broadcasted/incorporated. We didn’t even measure efficiencies of broadcast alone in our trials, but you could expect it to be even lower than 30 per cent. The bottom line is with liquid manure, get it in the ground to get maximum nutrient recovery efficiency as well as obtain other benefits like reduction in odour.

The microbial transformations that applied manure nitrogen undergoes in the soil, including nitrification and denitrification, can result in production of nitrous oxide. Work by graduate student Grace Dauk found that application of urea or injected liquid manure at an agronomic rate didn’t result in a big nitrous oxide flux, but when the rate of manure was doubled, there were higher nitrous oxide emissions.

One of my graduate students, Chadrick Carley, looked at the effect of nitrification inhibitors added to liquid manure. We found that the inhibitor was effective in keeping nitrogen in the ammonium form, and preventing nitrification and subsequent denitrification over the first three or four weeks of the season. Ultimately, because we had unusually dry conditions in the two years the trial was conducted, we didn’t see a significant end effect of that inhibitor on increasing yield or nitrogen recovery. I would anticipate the inhibitor would be much more effective under wet conditions which are much more conducive to losses of nitrogen through the denitrification and leaching processes.

Our research on injecting solid cattle manure in bands measured agronomic responses. We monitored agronomic performance over three years and saw slightly better yield and nutrient recovery when manure was placed in the soil versus surface broadcast. But in all fairness, the cattle manure we used wasn’t conducive to high volatile ammonia losses to begin with because it had a lot of straw in it along with low ammonium content. I think that if we used another manure source that maybe had more urea and ammonium in it, we may have seen more benefit from injection than what we did.

Interestingly in this work with solid manure, injection didn’t reduce the loss of phosphorus in surface runoff compared to surface placement. We think that subsurface injection was creating some channels below the surface in which water moved more readily. As well, by putting that manure below the surface, decomposition and release of soluble forms of nutrient that move more easily in snowmelt runoff may have been enhanced.

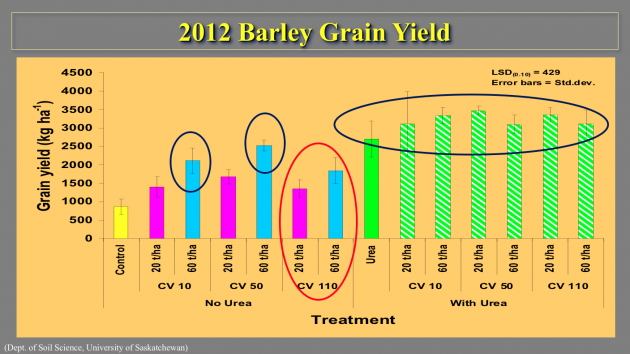

Uniformity of application across the spread area is also important. Old, worn-out manure application equipment can contribute to rather uneven manure application and distribution across the field. A study led by PAMI, Dr. King and myself, looked at the effect of differences in uniformity of solid cattle manure application on yield and soil nutrients at two rates: 20 and 60 tonnes per ha. We created different degrees of variability in manure distribution across the applicator width by combining manure from different outlet tubes. Treatments included relatively uniform distribution with a 10 per cent coefficient of variation, a second treatment with less uniform distribution with 50 per cent coefficient of variation and a third non-uniform treatment with 110 per cent coefficient of variation.

The first year oat crop in 2011 didn’t have a huge response to manure nutrients in general. In 2012, we grew barley and had a good response to manure application at 20 and 60 tonne per hectare. But with the highly variable 110 percent coefficient of variation application, we didn’t get nearly as good a yield response. When we added urea nitrogen along with that manure in those plots, the fertilizer tended to compensate for some of the negative effects of poor manure distribution on yield. The manure we used had a high carbon-to-nitrogen ratio, so not a lot of available N was released from the manure in the year of application.

The new manure spreading equipment with vertical beaters does a really nice job of spreading manure uniformly across the application width. We have one of these applicators for our new manure research that is variable-rate-equipped so that the rate of manure application can be varied across the landscape.

We need to be thinking more about how we can more “precisely” manage manure. Certainly I think we’ve come a long ways from simply dealing with manure as a disposal issue to considering how we can get the most benefit out of the nutrients and organic matter it contains. And, just like with commercial fertilizer, we can get more benefit if we precisely manage it.

More from the 2019 Soil Summit

Watch Jeff Schoenau explain the benefits of manure over fertilizer and tips for farmers and agronomists when it comes to manure in his Speaker Spotlight video. To see other presentations and speaker spotlight videos, visit our archives for the 2019 Soil Management and Sustainability Summit.