Features

Technology

Smart farming and glimpses into the future

Making management decisions with the help of smart ag technology and all of its data.

June 24, 2020 By Presented by Joy Agnew, Director of Applied Research, Olds College, at the Top Crop Manager Plant Health Summit, Feb 25-26, 2020, Saskatoon.

Autonomous equipment operation is an upcoming area of research for Olds College. Photo courtesy of Joy Agnew.

Autonomous equipment operation is an upcoming area of research for Olds College. Photo courtesy of Joy Agnew. Agriculture is a risky business, and that’s what the value of “smart” ag or ag technologies really is about – it’s to help mitigate that risk. Data and technology can help producers make decisions that account for all of the things that affect the overall profitability and productivity of farming. Weather and climate change, high and fluctuating cost of inputs, market volatility, that insanely complex relationship between soil, plants, air, and water, long-term impacts of cropping on soil health, and declining soil health, labour shortages, logistical challenges: all of it.

One thing that is confusing is the definition of “precision” ag, and what’s the difference between “precision” ag and “smart” ag. Olds College’s definition of smart agriculture is “utilizing technology and data to make science-based or evidence-based decisions to improve overall productivity, profitability, and sustainability of agricultural production.”

The classic definition of precision ag is using technology to account for or deal with the variability within a field. So while precision ag addresses variability within the field, smart ag goes beyond that by basing management tasks not only on location or variability within the field but also based on data, historical and potentially future forecasted data, enhanced by context and situation awareness, triggered by real-time events.

A few words on big data, because that’s really what precision ag and smart ag are based on, and that is utilizing data. Everyone’s talking about “big data” but big data is only useful if the little data has not been ignored for the last couple of decades. For example, if you don’t know your own cost of production, then you shouldn’t even be thinking about “big” data. You need to be focusing on the little data and use it well before you start thinking about incorporating big data into your management decisions.

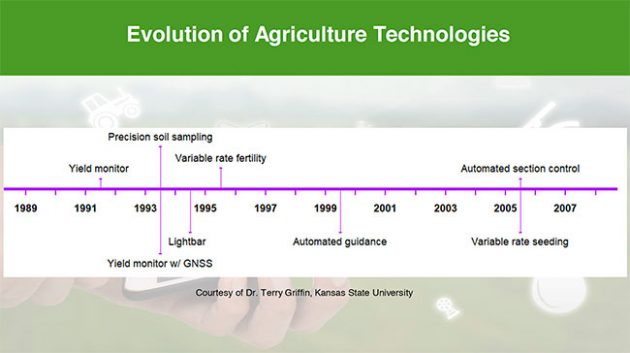

Dr. Terry Griffin out of Kansas State University put together a timeline of the evolution of agriculture technologies. Yield monitors were introduced in the early ’90s, precision soil sampling was big back in the ’90s, variable rate fertility was introduced in the ’90s, automated guidance was becoming much more popular in the 2000s, and sectional control and variable rate seeding were introduced around 2005.

In the last 10 years, the ag tech evolution isn’t bringing anything new to the table. It’s just improving how we might be able to do some of these ag technology practices better.

What’s the new current state and what’s coming out in the next few years? We are going beyond yield monitoring to do yield mapping. Rather than having an average bushel per acre on a field, we’re mapping it within discrete sections of the field to know the kind of productivity that is found in various parts of the field.

Instead of scouting or relying only on boots-on-the-ground in a field, there’s micro-climate and crop sensors and RPAS scouting to support boots-on-the-ground evaluations. RPAS is the new term for drones. It’s “remotely piloted aircraft structures” using imagery and remote sensing for scouting and looking at things like disease pressure or weed pressure or sometimes even staging.

There is a lot of talk about robot agronomists being available in the next five to 10 years. I’m not really sure how realistic this is going to be, mainly because of the nuances in determining crop staging. I’m not convinced that remote sensing or robot agronomists are ever going to be able to key in on those nuances.

courtesy of Dr. Terry, Kansas State University.

Instead of blanket application of herbicides, there are opportunities to do variable rate application of herbicides or other pesticides, or targeted applications based on technology like optical spot spray technology. Further out, autonomous swarms of micro-bots kill weeds without herbicide. There is a lot of interest in being able to utilize non-herbicide methods of killing weeds in an autonomous way that could help deal with some of the herbicide-resistant issues that agriculture faces.

Soil sampling has moved from just taking a composite sample across the entire field to precision soil sampling or high-density grid sampling with improved analytics. Instead of soil sampling, there is a technology that is claiming to eliminate the need for soil sampling. This provides in-the-field real-time continuous sampling or assessment of soil constituents, including plant-available nutrients, texture, temperature, EC, everything that you need in order to make a prescription map, theoretically.

Automated guidance is moving to smarter guidance and on to autonomous operation. I’m sure everyone has seen or heard of DOT and other OEM options for autonomous agricultural operation.

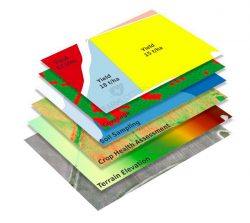

Variable rate prescriptions based on a single data layer are moving towards multi-layer data for prescription mapping. And then there may be no need to even generate a map because you’re going to be able to apply herbicide or fertilizer variable-rate in the field with a real-time soil nutrient sensor.

Instead of just mapping yields within the field, there is technology to map yield and quality within the field in real time on the combine, knowing exactly what your protein, oil, and starch content is, and whether there’s glyphosate residue on the crop going into the tank in the combine. That real-time analysis on the combine is possible and coming.

These are all very cool technologies, but I’m also very skeptical and somewhat practical when it comes to “What is the value to producers?” We can collect 6,000 data points per acre using this soil nutrient sensor, but what value is 6,000 data points per acre to a producer? How is that helping them make management decisions that actually put money in their pocket? That is the focus of our research at Olds College.

Ag data management platforms

One of the very first internal projects we decided to tackle was utilization of ag data management platforms. We selected five, but there are dozens if not a hundred of these management platforms available for producers. The five were from Trimble, Climate Fieldview, Decisive Farming, AgExpert Field and Farmers Edge.

We operated all five of these on our entire farm last year and looked at things like functionality and options, what does it help us manage, how easy is it to use, how easy is it to unload data from the equipment into the platform, and what kind of security and stability does it have? Our key question was which tool is the best fit for different applications? The Olds College Smart Farm has both cropping and livestock operations, so we’re able to look at platforms from a variety of different angles. This study will be ongoing because one year of experience with these data management platforms isn’t enough, and we will probably add additional platforms as they become available.

Mapping movement of livestock

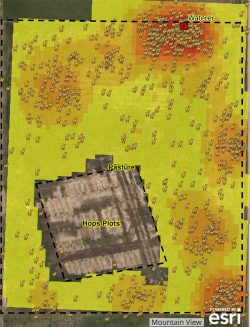

We had a student project with some GPS livestock collars that were donated to the College. They put the collars on some sheep to do a mapping exercise to track animal movement. The GPS collars provide real-time live tracking of animal movement. Once that data was downloaded and mapped, they created a heat map of the movement of a single sheep over the course of four days to see where it was spending most of its time. Where it was most of the time was around the watering bowl. The question that we’re now asking about this technology is can animal behaviour be easily monitored and then managed to improve herd health?

Soil and climate sensor validation

Our soil and climate sensor validation research is growing and it’s going to be ongoing for several years. There are numerous soil sensors and microclimate sensors coming onto the market but we have a lot of questions about them. What connectivity options do you need to provide real-time data that is going to be useful for management decisions? How robust are they? Do they have to be taken out every fall? Do they have above-ground portions that have to be managed during in-field operations? What is the quality of the data? How accurate are the measurements?

Our soil and climate sensor validation research is growing and it’s going to be ongoing for several years. There are numerous soil sensors and microclimate sensors coming onto the market but we have a lot of questions about them. What connectivity options do you need to provide real-time data that is going to be useful for management decisions? How robust are they? Do they have to be taken out every fall? Do they have above-ground portions that have to be managed during in-field operations? What is the quality of the data? How accurate are the measurements?

An interesting example of the usefulness of this technology is a micro-climate sensor that we looked at last year. One of the outputs of this particular sensor is leaf wetness index, and it was theoretically supposed to help you with timing of fungicide applications. But the reading that came back to us on leaf wetness index was an uncalibrated number on a scale from zero to 10. We went back to the technology developers and asked what the number meant. It turns out they had never deployed their technology or looked at their algorithm for a cereal crop. They were designed and implemented for row crop production in the United States. So what is the applicability to western Canadian agriculture? That is what we’re always interested in.

One type of soil sensor we are testing required us to dig a trench to place these sensors at various depths. They provide soil temperature and soil moisture at various depths. But we wonder what digging that trench did to the soil structure and the infiltration rate of that soil? And how comparable is that to the majority of the soil in a field that didn’t have a trench dug in it? The required density of these sensors for management decisions is another question we are trying to answer, knowing the optimum density of sensors will be dependent on field variability.

Compilation and utilization of data layers

We are looking at the compilation and utilization of data layers. A lot of companies are utilizing data layers for prescription mapping. But from a research farm perspective, we realize that we need to come as close as possible to having a calibrated soil. We have technology developers coming to us to validate assumptions or help them correlate their readings with the “true” reading. So we are developing the hyper-layer of data concept to as many of our fields as possible. These “calibrated” soils will help us validate and optimize these technologies, as well as help us define zones within that field for in-field trials of other technologies.

Remote sensing

Remote sensing with RPAS, remotely piloted aircraft structures, and the associated imagery can be a benefit to agriculture. The imagery can be thermographic, multispectral, hyperspectral, NDVI, RGB, or using more innovative things like ground-penetrating radar. Imagery is a very important data layer that can be used for management decisions or understanding soil variability.

Remote sensing with RPAS, remotely piloted aircraft structures, and the associated imagery can be a benefit to agriculture. The imagery can be thermographic, multispectral, hyperspectral, NDVI, RGB, or using more innovative things like ground-penetrating radar. Imagery is a very important data layer that can be used for management decisions or understanding soil variability.

There is a lot of interest in herd health management with thermographic imagery. Research has already been done showing that you can use thermographic imagery to detect disease or health issues in animals days earlier than symptoms appear, but that has to be done on an animal-by-animal basis and fairly close up. Using thermographic imagery to scan entire herds in a much shorter period of time for herd health management holds a lot of potential.

Autonomous equipment operation

A lot of questions and trepidation around autonomous ag, mainly on the regulatory and safety and efficiency side, still exist. Over the next few years at Olds College we will be operating DOT for as many operations as possible on as many acres as possible to start getting third-party unbiased information on overall functionality, fuel efficiency, the effect on soil compaction, and actual labour requirements.

One of the big selling features of DOT or other autonomous ag technology is that you can supposedly set it and then go do something else. There are questions around that. Does it have to be monitored? What kind of skillset is required to set this up and then troubleshoot it when it stops? We are going to be operating DOT as a commercially operating farm for as many acres as possible to try to answer these questions.

Optical spot spray technology

We are working with an optical spot spray technology called WEED-IT. Rather than blanket-applying herbicide across the entire boom width, WEED-IT optical technology looks for green and sprays only the green in real-time. It is well suited for pre-seed or pre-emergent application, or possibly pre-harvest or post-harvest application as well. There are a lot of early adopters in Alberta and Saskatchewan that are utilizing this technology for their operations. But we have questions about its functionality and its efficiency for western Canadian conditions. Specifically, how stubble type, travel velocity, and the size and type of weeds are going to influence the effectiveness.

Again, we are trying to develop a third-party, independent, unbiased evaluation of the chemical use reduction and overall efficiency of this technology. We’ll be looking at chemical use reduction with a variety of treatments, and monitoring crop and weed pressure throughout the growing season, and ultimately assessing the effect on yield as well.

Real time soil constituent analysis

This is a technology from a company called SoilReader. A sensor is mounted on a disc, and it is measuring the spectral bands as it goes through the soil for up to 15 soil constituents. It can measure nutrients, temperature, pH, EC, and even texture, at several different soil depths up to six inches deep.

Their tagline is, “We’re digitizing soil. Six-thousand data points per acre.” How does that actually help make management decisions though? There are still so many unknowns. We need to find out if there is value in knowing 6,000 real-time soil constituent data points per acre.

Future projects

We have another 10 or more projects that are in in the planning stages at Olds College. There’s technology for real-time seed depth adjustment, and coulter-by-coulter seed depth adjustment based on soil moisture during seeding and several other pre-commercial and commercialized precision ag technologies of interest for western Canadian implementation.

Quantification of the economic and environmental benefits of sectional control fertilizer application is another project. What effect does that have on overall carbon footprint of agriculture, and what is the actual percent reduction in fertilizer use due to reduced overlap?

Real-time soil constituent analysis is an up-and-coming

technology.

Traceability systems for bulk commodities to reduce food loss are another area of interest. There are a lot of companies with interest in utilizing technology along the entire agri-food supply chain. Automatic grain sampling systems for quality control and improved grain marketing opportunities is another area. Precision beekeeping with sensors can give you a sense of hive health, or what kind of pollination activity is happening in the area.

I want to measure and share return on investment of these technologies to producers. I very quickly realized that is much easier said than done, because ultimately most on-farm decisions boil down to dollars. And in some cases it’s easy to assign a dollar value or an economic value or an economic return to a technology or practice, but a lot of times it is hard to account for enough of the value or the benefit of the technologies. The value of technology or the value of being of being able to make decisions or adopt practices has to be broader than just dollars.

But even if we can define a measurable value to something like a yield increase due to variable rate technology, the spatial and temporal variability of that yield make it very difficult to measure ROI. That spatial and temporal variability of crop yield is massive and it’ll require hundreds of site-years of data before we can even have any kind of confidence in what that ROI really is based on yield alone.

So most likely ROI is going to have to be a range of values. The ROI or the payback period of something like variable rate technology is going to be a range, and it might be a big range of three to seven or three to 10 years. If you happen to adopt and utilize variable rate technology in a year that variable rate is very beneficial, then it might be a three-year payback, but it could be 10 years under other environmental conditions.

Challenges to technology

The ag tech evolution is going to have challenges. The most obvious one is one of the most aggravating, and it is the imperfect matching of technology. Basically we have technology companies in another industry who have a great technology and want to fit it into agriculture. They don’t understand the constraints or the problems associated with agriculture. That’s been the biggest frustration for me over the last year, seeing all these square pegs trying to be fit into round holes. Let’s understand the hole first and then design the peg to go in it.

An even more frustrating challenge is the translation of data into an actionable insight. I have learned very quickly that it’s so easy to collect terabytes and terabytes of data , but turning that into something that actually helps you make a management decision is a different ballgame altogether. So bridging that gap between collecting the data and turning that into something that’s useful, that’s another big challenge. More data does not necessarily result in more economic value.

Another gap is the limited access to expertise for innovators and small to medium-size enterprises to take their idea and turn it into a commercial product. In the ag industry, you need a pretty broad spectrum of expertise and infrastructure to be able to turn a basic idea into something that is going to be commercially viable. You need people with agronomic backgrounds and business backgrounds and technological backgrounds and experience with communication protocols and various other aspects of technology. We’re starting to build that at Olds College, and at the same time helping producers understand what the value really is.

All these evolving technologies are going to require dynamic learning opportunities for farmers and agronomists, because the technologies are changing all the time. There needs to be a place for agronomists and producers and crop advisors to learn.

Olds College is addressing many of these challenges with our Smart Farm platform. Olds College always had a commercially operating farm – 2,000 acres, about 700 acres of crop and 1,300 acres of forage and pasture land. We have infrastructure for innovation, validation, demonstration, and scaling. And we are also forming ourselves as the hub for a pan-Canadian smart ag ecosystem.

Olds College is launching two new ag tech programs this fall, a post-diploma certificate and a diploma in “techgronomy.” It’s a combination of technology and agronomy. These programs are going to be graduating very unique skillsets. We are also in the approval processes of getting our first four-year degree approved at Olds College, and that degree would be in precision ag.

Extension and dissemination is also going to be part of getting information out. The AgSmart Expo in August is one of our main dissemination platforms. We are also developing research reports and webinars and presentations.

The Strategic Innovation Fund from the federal government has provided funding for a network called the Canadian Agri-Food Automation and Intelligence Network, or CAAIN. The goal of CAAIN essentially is to advance and adopt automation and digitization technologies for agriculture. Olds College and Lakeland College and Alberta Innovates are three core partners within this group, and we’re expecting the money to start flowing this year for projects.