News

Setting up a shochu barley value chain

"Kampai” is a common Japanese toast before a meal, and more Alberta farmers are likely to be using it in the future. Shochu, a fermented and distilled liquor, is a growing market opportunity for Alberta barley thanks to efforts by the Alberta Barley Commission, Alberta Agriculture and Rural Development (AARD) and Rahr Malting Canada Ltd. in Alix, Alberta.

February 24, 2010 By Carolyn King

|

|

| Field trials at Lacombe, Alberta, are helping to determine which barley varieties are best for shochu. Photos courtesy of Bill Chapman.

|

"Kampai” is a common Japanese toast before a meal, and more Alberta farmers are likely to be using it in the future. Shochu, a fermented and distilled liquor, is a growing market opportunity for Alberta barley thanks to efforts by the Alberta Barley Commission, Alberta Agriculture and Rural Development (AARD) and Rahr Malting Canada Ltd. in Alix, Alberta. “Shochu is like a very smooth good-quality whiskey; you drink it with water or juice or on ice. Some of the more popular and more flavourful types of shochu are made out of barley, but it can also be made out of other crops like buckwheat, sweet potato or rice,” explains Bill Chapman of AARD.

The shochu market has excellent potential for barley growers for several reasons. First, it’s a premium market. According to Chapman, shochu barley is competitively priced with malt barley, allowing growers to increase their returns per acre without increasing their risk or input costs.

It is also a growing market. “Shochu is very popular in Japan with businesspeople, and an important part of their business culture. It is a major market there that’s seen a lot of growth in the last 10 years,” says Chapman. He says annual sales of shochu have increased by 20 to 40 percent in recent years.

And Japanese shochu makers are interested in our barley. Rahr’s vice-president of marketing Bob Sutton, explains that Japan’s shochu market uses roughly 250,000 tonnes of barley per year, mostly sourced from Australia. However, concerns regarding the effects of persistent drought on Australia’s barley supply prompted Sanwa Shurui, one of Japan’s largest shochu makers, to look for additional barley suppliers.

Sutton says, “Definitely a key for Sanwa was diversification of supply. When your exclusive supplier begins to have crop issues, you want to take a look around, and it was found that our Metcalfe barley has the potential to be as good as some of the Australian types. It’s not going to replace all of the Australian supply, but it does give shochu makers another source.”

Shochu barley’s strong market potential led the Alberta Barley Commission, AARD and Rahr to initiate a project to develop a value chain to supply Alberta barley to the shochu market. “Our goal is to export between 60,000 and 90,000 tonnes per year of barley, and that’s why we’re excited. That would make us the number two supplier of shochu barley to Japan, and that’s our goal by 2013, subject to crop quality,” says Chapman.

The project includes research and marketing activities to make sure the Alberta product meets the requirements of Japan’s shochu market.

|

|

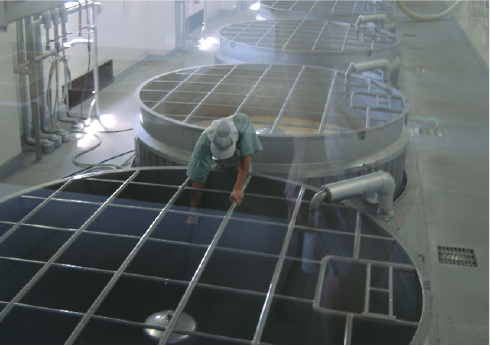

| Fermentation is one stage in the production of shochu, a liquor drink. | |

|

|

| Representatives of Sanwa Shurui, one of Japan’s largest shochu makers, visit with Dr. Jim Helm (second from right) of Alberta Agriculture and Mike Leslie (far right) of the Alberta Barley Commission, who are both involved in the value chain project. |

Seeking the best shochu barley varieties

As part of the project, researchers are conducting field trials in 2008 and 2009 to determine which barley varieties are best for shochu. Shochu barley has to be very plump, uniform and have an average kernel hardness between 58 and 60. Kernel hardness is the most important characteristic because the kernels are pearled before they are fermented and distilled to make shochu, so the kernels must be soft enough to pearl but not so soft that they crack or break during pearling.

The field trials are comparing 26 barley varieties, including some not-yet-registered lines bred by AARD’s Field Crop Development Centre at Lacombe. “We’re growing all the current cultivars of two-row barley that we thought might be important for the shochu market,” says Dr. Patricia Juskiw, a barley breeder with AARD who is leading the trials.

The trial’s sites represent some of Alberta’s main barley-growing regions. They include a site at AARD’s Lacombe Centre as well as three locations in co-operation with applied research associations: the Battle River Research Group’s site is near Killam in east central Alberta, the Gateway Research Organization’s site is near Westlock, north of Edmonton, and the Smoky Applied Research and Demonstration Association’s site is near Falher in the Peace River region.

Growing all the varieties at each location under the same conditions allows the researchers to evaluate the effects of both genetics and environment on shochu quality. Juskiw explains, “You can look at all the locations and see, for instance, that this one particular cultivar is always better, whereas another one is okay at one location but not at another location, and maybe some other cultivar is not good at any of the locations.”

The seed from the trials is analyzed for various shochu quality characteristics like kernel hardness. As well, Dr. Darcy Driedger, a food scientist with AARD, is assessing the seed in pearling trials and in tests related to the fermentation process. And samples from the 10 best varieties have been provided to Japanese shochu makers so they can conduct their own analyses.

The results from the 2008 trials indicate that AC Metcalfe is a very good choice for the shochu market. Also, some of the new barley lines currently in the registration process look promising.

Juskiw says evaluation of barley lines for shochu quality will continue after 2009, although perhaps not in the same format. She explains, “In our barley breeding program, we test all of our advanced materials for malting quality, shochu or pearling quality, some food characteristics, like starch and fibre content, and feed quality.”

Along with identifying which of the 26 varieties are best, the trial results could help in finding other possible shochu varieties. “In the process of this project, we are trying to see if shochu quality, especially kernel hardness, is always related to some specific set of traits,” notes Juskiw. If such a relationship is found, it will be easier to sort through existing barley lines to find those with good potential for shochu.

Juskiw explains that at present it is not practical to breed a variety specifically for shochu. “There would have to be a big enough market so we could get growers to take the risk of growing a variety specifically for shochu. Ideally we’d like a multiuse variety that is the best for everything. For instance, a variety like Bentley, a recently registered variety developed by the Lacombe breeding program, has good malting quality and it’s also a good feed variety in that it’s got really high biomass yields and high grain yields. So producers have a lot of options with it.”

Better quality testing

Rahr’s role in the value chain is to conduct quality testing and co-ordinate the shipments of shochu barley. “Most of our work is involved in selecting the right barley from the individual farmer samples to be able to put together shipments that meet all of the requirements of the market,” says Sutton.

To evaluate barley quality for shochu, Rahr uses a variety of testing tools including near-infrared reflectance spectroscopy (NIRS), a single kernel characterization system that measures kernel hardness, and Japanese pearling machines.

As part of the value chain project, AARD is developing shochu-specific NIRS calibration curves for commercial use. Chapman explains, “Using NIRS, it only takes a few minutes to analyze a seed sample and a few more minutes to do the computer work to give you the sample’s spectrum. NIRS compares the sample’s spectrum to a standard spectrum of grain quality and multiple factors like starch content. We do have NIRS calibrations for the research work, but when you get into commercial samples from different locations, the spectrums change slightly. So that’s where the review and determination of the calibration curves come in.”

Great progress, greater potential

Already, the efforts of the Barley Commission, AARD and Rahr are having a noticeable effect on shochu barley exports. “In 2008, Rahr exported 10,000 tonnes of shochu barley to Japan, and Japan has tentatively ordered 15,000 tonnes before the end of the 2009 crop year. So that’s a major jump from the smaller amounts they were taking previously,” notes Chapman. For instance, Rahr shipped 5,000 tonnes of shochu barley to Japan in 2007.

Sutton says, “We’ve been doing commercial shipments of shochu barley for the last four years. Every year we’ve had a target to be able to ship better quality and try to catch up to where the Australians are, and this year we were finally able to match the Australian quality. So that should be good for the future.”

He adds, “If we could build our exports to be a third of the shochu market, I think that would be very successful. And if we happen to develop better varieties then we can maybe look at even going beyond a third of the market.”

The value chain project is funded by Agriculture and Agri-Food Canada’s Advancing Canadian Agriculture and Agri-Food Program (through the Agriculture and Food Council of Alberta) as well as AARD, Alberta Barley Commission, Rahr Malting, Alberta Crop Industry Development Fund, Growing Forward, Agriculture Council of Saskatchewan and Investment Agriculture Foundation of British Columbia.