News

Seed tenders replacing bags

When Manitoba Interlake seed grower Bruce Stewart got a seed tender, he quit throwing bags.

May 3, 2010 By John Dietz

When Manitoba Interlake seed grower Bruce Stewart got a seed tender, he quit throwing bags.

|

|

| The Meridian Titan 2SE is an example of a seed tender that can improve seeding efficiency. (Photo courtesy of Meridian Manufacturing) | |

|

|

| Yetter’s Seed Jet II uses air to move bulk seed from a hopper bin to the seeding equipment. (Photo courtesy of Yetter Manufacturing) |

|

|

|

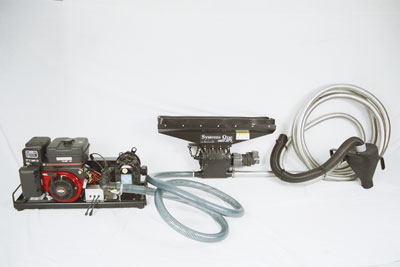

| The components of Yetter’s Seed Jet II. (Photo courtesy of Yetter Manufacturing) |

“It saved time. We do a lot of custom planting. We use it with the corn planter, and a little bit for soybeans. We use it as a bulk container for holding seed. It’s simpler, and I’ve got a few guys interested in it, as well,” Stewart says.

Stewart is a sales rep for Pioneer Hi-Bred brand seed products, and uses a Titan 2SE seed tender Titan 2SE (retailing at around $12,500). Meridian introduced the Seed Titan series to western Canada in 2008. It is designed to carry the Pioneer Hi-Bred Probox seed container, says Sid Lockhart, Meridian marketing manager.

For growers like Stewart, Seed Titan is a middle-ground option between bulk seed, jumbo bags and 50-pound seed bags, and serves as an example of the many choices available in seed tenders. The Pioneer Hi-Bred Probox is a stand-alone product that has been a popular option in southern Manitoba for more than five years. Pioneer Hi-Bred markets corn, soybeans, canola, sorghum and winter wheat in the reusable Probox. The rigid injection-molded container holds up to 50 units of seed, equivalent to 2500 pounds.

Probox has an easy-open flow control slide under the centre drain. It allows one person standing beside the container to safely and easily unload all or part of the seed. The seamless interior can empty fully in 30 seconds.

A forklift, a front-end loader with pallet forks, or a three-point forklift attachment on the rear of a tractor can be used to transport, stack and unload the container. The container also is nearly weather-tight and protects seed from pests during storage.

While the Probox can be used on its own or with other seed tenders, several models of Meridian’s Seed Titan can carry two or four Probox units on the seed tender which, in turn, is on a trailer for highway or field transport.

To unload, operators start the engine, activate the six-inch cleated conveyor, swing the top end of the conveyor out over the planter or air seeder, and pull open the slide chute at the bottom of the PROBOX. Seed pours onto the belt, which carries it safely and without damage to the planter or air seeder. The chute can be closed manually at any point. “There’s a huge saving to the producer in time and safety because he doesn’t have to climb up and down a ladder hauling bags. It only takes minutes to load, and you don’t have to deal with empty bags,” says Lockhart.

Canola option

Canola growers currently have two choices for loading seed. Many empty the canola seed bags, one by one, into the intake auger for the air seeder. It can lead to seed damage and require growers to dispose of the bags.

The other choice is to carry the 50-pound bags up the ladder to the hatch on the air cart. That’s a physical challenge and poses high risk. It may lead to a spilled-and-broken bag of high-value seed, to personal injury, to bits and pieces of bags in the air tank, and it still requires growers to dispose of the emptied bags. “I really don’t like putting seed through the auger of an air seeder. We’re looking for a safer way to handle the seed,” says Darcy Rafoss, Pioneer marketing manager for end use and service at Wynyard, Saskatchewan.

Probox with the Seed Titan is one option that may assist canola growers in Western Canada. The one limitation of the Seed Titan is elevation: most air seeder tanks are too high to reach directly with the Titan conveyor.

Meridian is now looking at options to address this issue. It was one reason Rafoss demonstrated the Seed Titan and Yetter Seed Jet II in 2009 across the Prairies. He plans to have at least five systems in place with the Pioneer Hi-Bred network of sales representatives for 2010.

One Probox loaded with canola carries enough seed for about 400 acres. If a grower purchases his own system, Pioneer can supply seed for the Probox or the grower can refill it with other seed. “One nice storage advantage is that you can stack them four boxes high, if you have the equipment to lift them,” Rafoss says.

Probox is designed for handling like a pallet.

The Yetter Seed Jet II, from Illinois, uses air pressure and can be used with a variety of rigid bulk containers, including Probox. It seems as gentle as the conveyor for canola, Rafoss says, and is popular in US row crop areas.

According to Yetter, the Seed Jet has proven safe with soybean, corn, wheat, rice, edible beans and cotton seed. It carries a powerful blower and air lock mounted on a trolley. The operator slides it below the seed box chute, attaches it to the box with the air lock, then opens the chute. An airstream then slides the seed through a flexible, 35-foot stainless steel hose. At the other end, a decelerator slows the seed and gently swirls it into a planter, drill box or air seeder tank.

Seed Jet is one component in a seed handling system (retailing at around $6500). It still requires a trailer or deck to carry the boxes.

Other options available

The Meridian Titan and Yetter Seed Jet tenders are only two examples of seed tenders. Bud McKnight, Pioneer rep at Carman, Manitoba, says about six companies are building their own version of seed tenders in the Red River Valley. Many tenders can handle either bulk bags or boxes. Bud McKnight Seeds retails seed and seed tenders, and has been serving growers since the early days of the corn industry in Manitoba.

McKnight sold a 40-foot tender with five compartments early in the winter of 2009-10. Tenders can have seven or even eight compartments, he says. The typical seed tender has two gravity-flow hoppers and a belt conveyor. It retails in the range of $10,000 to $15,000 on a trailer with tandem axles. “These tenders can be on their own running gear, or they can be deck mounted on some other piece of running gear. For big tenders, we get triaxle container trailers 40 feet long and put them on those.”

Tenders have been used in the valley for about 10 years, he says. They are popular because growers get 100 percent cleanout and can handle several lots on a single tender. They have been replacing traditional seed bags and jumbo jute bags. McKnight no longer retails seed in jumbo bags. “Guys change because it’s harder and harder to get people who want to throw bags in spring,” McKnight says. “They’d much rather flip a switch to fill the planter or air seeder than start lugging bags and dumping them in.”

The typical changeover goes like this, he says. For years, a grower comes in each spring with his pickup. It gets loaded with 50 or 60 bags of seed, and off he goes to the field. Now, he pulls into the retailer with a seed tender behind the pickup, McKnight fills the Probox on top in about two minutes, and the grower heads off to his field.