Features

Herbicides

Seed & Chemical

Tips for herbicide tank-mixing

Chemical injection systems should be rinsed between pesticides. Photo courtesy of Bestway.

There was a time when loading up the sprayer tank was as simple as filling the sprayer tank one-half full of water, adding the herbicide with agitation, filling the tank and going spraying. In some cases today, though, you almost have to have a chemical engineering degree to mix up the herbicide cocktail. Add everything in the correct order and life is good. If you tank-mix products incorrectly, you could experience sediments in the spray tank, gelling, and plugging of nozzles and filters.

“The first thing you should ensure is that the tank-mix is either on the label or supported by the manufacturer. If the tank-mix is supported, you know the manufacturer has spent time researching the product and understands how to mix the products together,” Brian Wintonyk, agronomy leader with Dow AgroSciences at Calgary, Alta., says. “The label and the manufacturer should be your first sources of information.”

Wintonyk says before adding herbicides, growers should ensure the sprayer tank is cleaned so residues do not hurt sensitive crops. Additionally, he says to make sure the chemical injection tanks are thoroughly cleaned, and to rinse the injection tank between each herbicide addition.

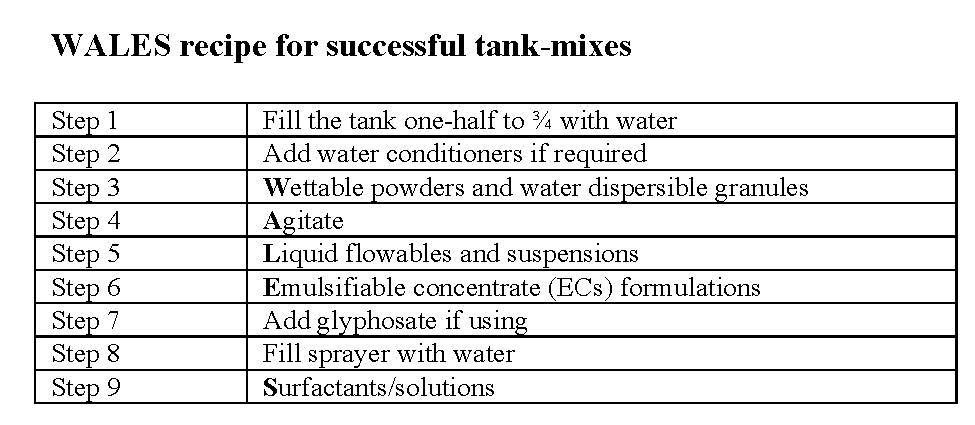

Use the WALES acronym

Adding herbicides into the tank in the correct order is critical to ensure herbicide compatibility isn’t compromised. Generally, following the WALES acronym is a good way to remember the order of products. Before adding any products, fill the sprayer tank with one-half to three-quarters of the required water. Any water conditioners, buffering agents or defoamers generally go in next. Then, follow the WALES sequence: Wettable powders and water dispersible granules; Agitate; Liquid flowables and suspensions; Emulsifiable concentrate (ECs) formulations; and Surfactants/solutions.

Suspension forming products like wettable powders (WP), dry flowables (DF) or water-dispersible granule products (WDG) should be added to the tank first. Adequate agitation throughout the mixing process is important and ensures products are well dispersed in the spray tank. Some of the new technologies in these formulations mix very readily, and with today’s sprayers, they can disperse rapidly in the spray solution.

Liquid flowable (F, FL) are added next followed by emulsifiable concentrates (EC). Finish filling the sprayer tank and add any surfactants.

Wintonyk cautions mixing of different product formulation types should be done carefully. Glyphosates are a good example because different undiluted glyphosate formulations may react with each other.

“If you add different glyphosate formulations into a chemical injector, you can end up with a Slurpee in the chemical handler. Avoid mixing different formulations, if possible,” he notes.

Of course, there can be exceptions so always check the label, and with the manufacturers, if in doubt.

May 19, 2015 By Bruce Barker