Over the last year, dozens of new models and designs of farm machinery have

been introduced by manufacturers. Many of you will have seen these introductions

at farm shows and in various industry announcements – but, can you remember

the details? This feature provides a reference for you. Peter Darbishire,

Editor

While Top Crop Manager editors make every effort to be objective

when reporting on new products, they cannot be held responsible for claims made

by companies. Readers are encouraged to contact the companies for more details.

Headers to match

Headers to match

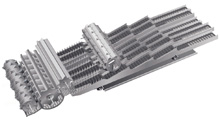

New Holland's two new combine headers match the capacity and productivity of

both the new CR9000 Series Twin Rotor combines and CX8000 Series Super Conventional

combines. The 74C flexible cutterbar header is available in three cutting widths,

including a new 35 foot width. Each is equipped with a twin knife drive. The

74C offers a choice of 1.5 inch knives and guards (twin cut) or 3.0 inch knives

and guards. It also provides up to 4.5 inches of float and closely follows the

ground contour to pick up low-growing crops. The New Holland Terrain Tracer

header flotation system is standard equipment.

Terrain Tracer follows the ground contour in rough, uneven fields. It automatically

tilts the header laterally to follow the ground contour and raises the head

vertically. If the combine dips into a gully one wheel at a time or crosses

a deep tire track, the header remains on the ground to get all the grain. Terrain

Tracer is offered for all New Holland direct cut, auger type headers and corn

heads.

The 99C corn head gets under downed corn, picks it up and takes in less trash

for more combine capacity. It is available in eight row rigid, eight row folding

and 12 row rigid configurations. The divider snouts are constructed of smooth,

durable polyethylene. The slippery surface of the shields, fenders and points

allow for smooth, fast feeding so the operator can work at increased ground

speed. The polyethylene construction also absorbs impact so ears do not bounce

out of the corn head.

The 99C corn head features heavy-duty cast iron row unit gearboxes to drive

and support the stalk rolls. The stalk rolls are heat treated and straight fluted,

knife rolls are more aggressive feeding than a tapered stalked roll.

The shields on the 99C corn head flip up and out of the way for complete servicing

and easy transport. It is also easy to adjust the height of the points without

tools.

New Holland

Threshing and separation system is wide

Threshing and separation system is wide

Designed for growers who want to harvest at faster speeds while maintaining

high quality grain and straw, Claas Omaha has introduced new straw walker technology

with the introduction of the Lexion 570 combine. It features six high performance

straw walkers and a 67 inch wide, award winning, Multifinger Separation System

(MSS) for improved threshing and separation of the grain. The 570, powered by

a 350 horsepower Cat engine, also features a high capacity grain cleaning system

with large sieves and a Lexion exclusive 280 bushel folding grain tank.

Claas Omaha

High capacity

Rem Enterprises' new grain vacuum, the model 3700, moves product at 10,000 bushels

per hour (272 tonnes per hour), says the company. It features low noise volume

and pitch, adjustable and lockable air throttle and a directional exhaust. It

may be used to move grain from a long distance or be hooked directly up to a

bin sump.

Company figures show capacity of 109 to 136 tonnes per hour with 15 metres

of pipe at full bin load-out and 150 tonnes per hour with 11 metres of pipe

with a 20 centimetre bin sump. The exhaust incorporates an adjustable directional

swivel. The vacuum can be unfolded next to bins and features torsional suspension

for smooth high speed towing.

Rem Enterprises

Storage and Handling

Smoother operation

Buhler released two new products at the Western Canada Farm Progress Show in

Regina, Saskatchewan, and the Farm Progress Hay Expo in Westgate, Iowa.

The Buhler Farm King grain handling division introduced its 1035 conveyor,

the first conveyor designed and built at the factory in Morden, Manitoba. This

10 inch by 35 foot conveyor represents the first step in an expanding line of

Buhler conveyors.

It is an 'A' frame in-line conveyor with a 12 inch belt running in a 10 inch

tube. Capacity is rated at 3000 bushels per hour. Its overall length is 37 feet

and it can load to a bin height of 17 feet 6.0 inches at 30 degrees or 15 feet

5.0 inches at 25 degrees. Transport height is 11 feet.

Buhler Manufacturing

Four fan types available

Westeel has added fans that can be used on both Westeel and competitive aeration

systems. The new line-up includes in-line centrifugal fans, axial blade fans

and both high and low speed centrifugal fans. Each fan type is ideal for specific

crop requirements and available in a range of horsepower options.

Westeel