Tractors

Ballasting for better tractor efficiency

Weighting a tractor for optimum efficiency means improved pulling performance, less fuel consumption, and longer drive-train life. Yet, for many farmers, ballasting remains a once per tractor-lifetime scenario.

May 25, 2010 By Top Crop Manager

Weighting a tractor for optimum efficiency means improved pulling

performance, less fuel consumption, and longer drive-train life. Yet,

for many farmers, ballasting remains a once per tractor-lifetime

scenario.

|

|

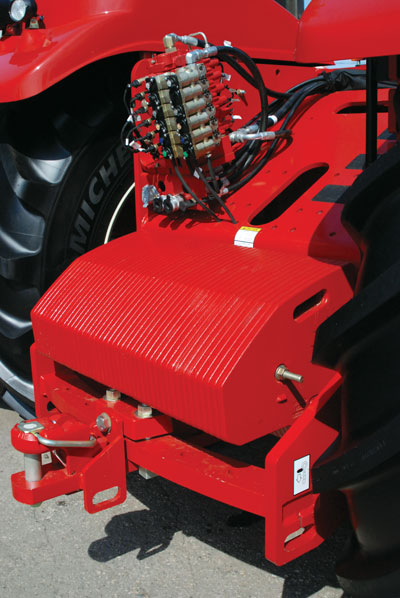

| A properly ballasted tractor uses less fuel, lasts longer and improves tractor efficiency. (Photos by Bruce Barker) |

|

|

|

| A mechanical front-wheel drive (MFWD) tractor should have weight distributed 40 percent on front and 60 percent on back. |

“For most folks, if the tractor ballast is looked at, it happens once

at the dealer,” says Roger Hoy, director of the Nebraska Tractor Test

Lab at the University of Nebraska at Lincoln.

Hoy explains that, ideally, a tractor’s ballast should be adjusted for

each field operation, but he also knows that may be impractical. As a

result, Hoy suggests ballasting for the most common field operation.

For many western Canadian farms, that likely means tillage and seeding

activities, especially for high- horsepower tractors.

Lawrence Papworth, an engineer with the AgTech Centre at Lethbridge,

Alberta, explains that the primary reason to assess a tractor’s ballast

is to control wheel slippage. Over-ballasting, which is the most

common, results in higher fuel consumption, sluggish tractor handling,

and premature drive-train problems. Over-ballasted tractor tires show

very little wear because they are not slipping in the soil.

An under-ballasted tractor will show excessive tire tread wear due to

excessive slip, and cannot deliver full horsepower to the drawbar. Fuel

is also wasted because of the excessive wheel slippage.

A rough guideline for wheel slippage is 10 to 15 percent for two-wheel

drive (2WD) tractors, and eight to 12 percent for four-wheel drive

(4WD) tractors. Papworth explains that these slippage guidelines

provide the most economical operating point where fuel consumption,

tire life, productivity and tractor durability are combined.

Estimate slippage

Slippage is relatively easy to measure in the field. The AgTech Centre provides this guideline for measuring slippage.

Mark the side of a drive tire with a vertical chalk line. Under normal

working conditions and on untilled ground, get the tractor and tillage

implement up to speed. Have a helper drop a flag beside the tire when

the chalk mark touches the ground. On the tenth tire revolution, drop

another flag on the ground when the chalk mark hits the ground.

Next, take the implement out of the ground, turn around, and drive back

alongside the tilled ground with the implement out of the ground. Using

the chalk mark as a guide, count the number of revolutions that it

takes for the tractor to cover the same distance while keeping the

tillage unit out of the ground.

Use the following equation to estimate slippage:

Percent slip = 10 minus the number of revolutions without load, divide by 10 and multiply by 100.

For example, if it took 8.75 revolutions with no load to cover the same

distance as 10 revolutions under load, the slippage would be 12.5

percent (10 – 8.75 divided by 10 multiplied by 100).

If the tractor is a 4WD or front-wheel assist, do the same thing on the front drive wheels to ensure slip is evenly balanced.

If wheel slip falls within range, the tractor is ballasted correctly

for the field operation. If it does not, consider changing the

ballasting.

Ballasting tips

Ideally, ballast could be changed for each type of field operation, but

that may be impractical, especially if calcium chloride is used in the

tires for ballast. However, many tractors now primarily use cast iron

ballast, which can be more easily added or taken off. Papworth says

that many of the high-horsepower tractors are much heavier than in the

past, so ballasting is more of a fine-tuning process to manage slippage.

Preliminary estimates for ballasting can be made based on horsepower

and travel speed. AgTech information indicates that, generally, higher

travel speeds require less ballast. The AgTech publication, Ballasting

Your Tractor for Performance, explains that “the mechanical properties

of the soil only allow so much deformation (slip) to occur in a given

period of time. For example, a faster rolling tire has less time to

cause deformation on a given area of soil; slip is reduced, and less

ballast is required.”

Papworth explains that at slower speeds, more ballast is required to transfer most of the tractor’s horsepower to the ground.

The AgTech publication explains that 95 to 110 lbs per engine

horsepower (79 kg/kW) is a rough starting point for estimating ideal

tractor weight including ballast at a speed of eight kilometres per

hour. The manufacturer’s recommendation on ballasting should also be

consulted. This estimate should provide a slip percentage somewhere in

the correct range when the tractor is fully loaded. But be aware of the

effect of different speeds: to get the same slip percentage at 6.5

kilometres per hour requires 163 lbs per horsepower (99 kg/kW) for

proper ballast; at 9.5 kilometres per hour, only 108 lbs per horsepower

(66 kg/kW) is required.

This guideline should be compared to the actual weight of a tractor.

The Nebraska Test reports also list the weights of unballasted

tractors. Growers can usually get a tractor’s shipping weight, complete

with additional equipment, from a dealer. A grain elevator scale is a

good way to check the actual weight if it is convenient.

Weight distribution between the front and back wheels also should not

be overlooked, says Papworth. The tractor type is important.

| Weight distribution for different tractor types | ||

| Type | Front | Back |

| 2WD | 25% | 75% |

| MFWD | 40% | 60% |

| 4WD | 55% | 45% |

Papworth says that over-ballasting is usually a more common problem,

because farmers are trying to squeeze out all the horsepower they can

from their tractor to pull large loads.

Another important point is to ensure tire inflation is correct.

Papworth says that once the proper ballast weight and distribution is

set, the tire pressure should be set for the corresponding weight on

each tire. Check the manufacturer recommendations for the weight

carried by the tires.

During the summer of 2010, AgTech in co-ordination with the

Agricultural Research and Extension Council of Alberta (ARECA) plans on

holding several ballasting demonstration throughout the province. Check

the ARECA website (www.areca.ab.ca) for further information.

*This article was provided by Alberta Research and Extension Council of

Alberta, with information compiled from the AgTech Centre Research

Update #725.