Category

Storage & Transport

Storage & Transport

March 9, 2018

March 9, 2018

New grain bag recycling program approved in Saskatchewan

Storage & Transport

March 8, 2018

March 8, 2018

CN promises immediate action to clear backlog of grain shipments

Storage & Transport

March 2, 2018

March 2, 2018

Rail shipment delays a serious issue for Canadian farmers

Storage & Transport

February 9, 2018

February 9, 2018

Optimize operations on your farm by incorporate weighing scales

Advertisement

Stories continue below

Storage & Transport

December 15, 2017

December 15, 2017

Canada’s grain farmers call on Senate to pass Bill C-49

Storage & Transport

September 17, 2017

September 17, 2017

AWC provides the producer perspective on grain transportation by rail

Storage & Transport

June 21, 2017

June 21, 2017

Aeration versus natural air drying

Storage & Transport

April 11, 2017

April 11, 2017

Spring moisture migration in grain bins

Storage & Transport

November 9, 2015

November 9, 2015

New grain rescue gear in Prince Albert, Sask.

Storage & Transport

September 4, 2015

September 4, 2015

Natural air drying simpler, cheaper

Storage & Transport

September 1, 2015

September 1, 2015

Preventing insect infestations when storing grain

Storage & Transport

July 22, 2015

July 22, 2015

Horsch SW750 Air Cart offers 750-bushel capacity

Storage & Transport

January 20, 2015

January 20, 2015

Reduce corn shatter loss

Storage & Transport

December 15, 2014

December 15, 2014

Tuning into radio-frequency heating

Storage & Transport

November 12, 2014

November 12, 2014

Time for November bin checks

Storage & Transport

July 22, 2014

July 22, 2014

Westfield launches drive over hopper

Storage & Transport

May 5, 2014

May 5, 2014

Spring warm up for stored canola

Storage & Transport

April 8, 2014

April 8, 2014

Manage stored grain before May 2014

Storage & Transport

April 3, 2014

April 3, 2014

The grain bin game plan

Storage & Transport

November 13, 2013

November 13, 2013

Check bins and bags on cold November days

Storage & Transport

October 30, 2013

October 30, 2013

Storing grain on the ground at licensed elevators

Storage & Transport

September 20, 2013

September 20, 2013

Big zippers seal out grain bag troubles

Storage & Transport

September 3, 2013

September 3, 2013

Canola combined hot requires aeration

Storage & Transport

September 3, 2013

September 3, 2013

Westeel expands line of Smoothwall bins

Storage & Transport

August 27, 2013

August 27, 2013

New imaging technology for grain bins in the works

Storage & Transport

June 24, 2013

June 24, 2013

New features on GBU10 grain bag unloader

Storage & Transport

June 17, 2013

June 17, 2013

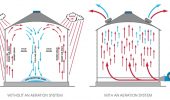

Effectiveness of different aeration systems

Storage & Transport

June 5, 2013

June 5, 2013

The new Dodge Ram

Storage & Transport

June 3, 2013

June 3, 2013

Cargill to expand rail capacity at Saskatchewan grain elevator

Storage & Transport

May 15, 2013

May 15, 2013

Viterra upgrades Saskatchewan elevators

Storage & Transport

May 1, 2013

May 1, 2013

Richardson acquires Viterra grain, crop inputs and milling assets

Storage & Transport

April 23, 2013